Jingnan Mould is a professional factory that has been involved in the design and manufacture of pallet moulds earlier in China. With years of technical accumulation and market experience, it has now grown into a high-quality supplier in the field of pallet moulds in the world. We always adhere to high standards and high efficiency in the development of pallet moulds, and widely serve multiple industries such as logistics warehousing, food processing, chemical transportation, cold chain distribution, etc. Jingnan Mould produces a wide variety of pallet moulds, including double-sided pallets, single-sided pallets, nine-foot pallets, grid pallets, flat pallets and other structural forms, which can not only meet the industrial use of heavy loads and high turnover, but also meet the needs of economical pallets for one-time export or light handling.

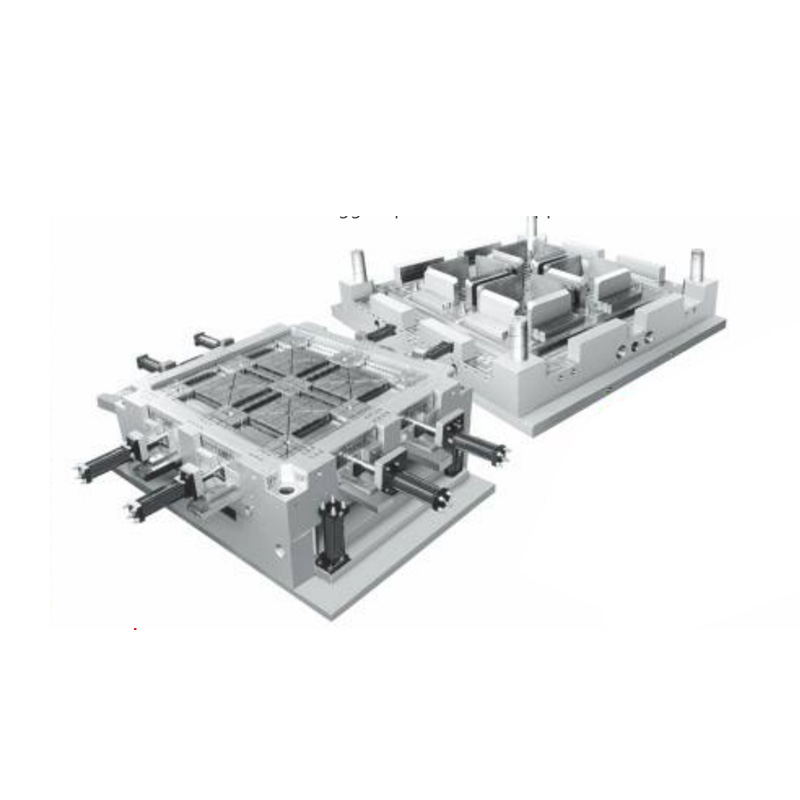

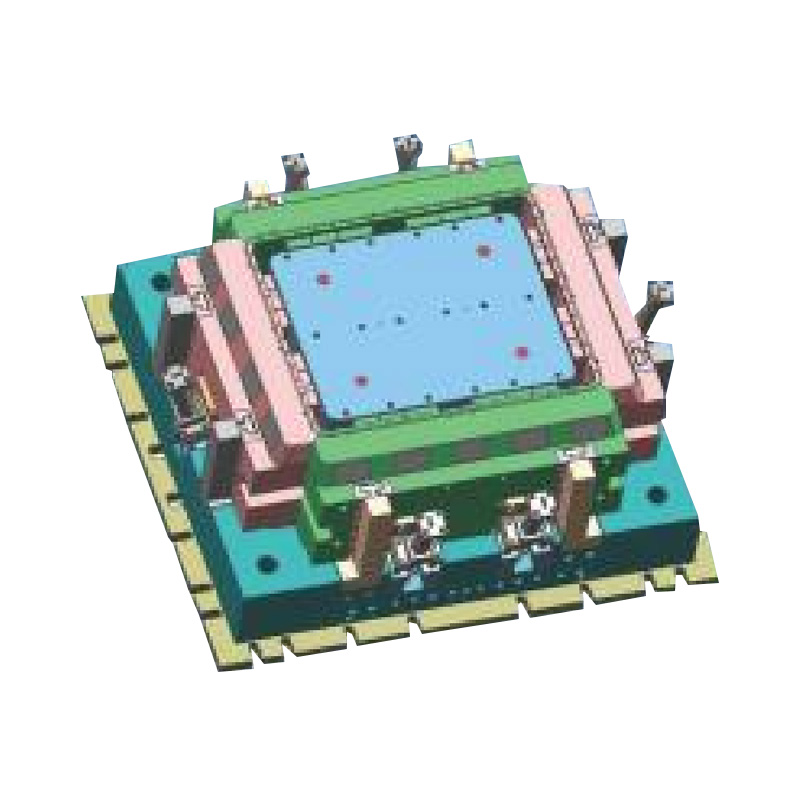

Most of the pallet moulds we develop are made of high-strength and high-quality mould frame steel, and professional heat treatment processes are used to improve the service life and wear resistance of the mould. In terms of design, with the help of advanced CAD/CAM/CAE systems and mould flow analysis technology, we ensure that the pallet is filled evenly, demoulding is smooth, and the structure is stable during the injection molding process, effectively avoiding common problems such as shrinkage and warping. At the same time, Jingnan Mould has the ability to develop multi-cavity high-efficiency injection moulds, which can be tailored according to the customer's production capacity requirements and automated production line configuration. We also support in-depth optimization of pallet structures, such as reinforcing rib design, non-slip surface, RFID or identification slots, and other functional integrations to meet the diverse application scenarios of different customers.

With rich manufacturing experience and strict quality control system, Jingnan Mould's pallet moulds are at the industry-leading level in terms of molding accuracy, mould life, and production efficiency, and its products are exported to the world. We not only provide manufacturing services for the mould body, but also provide customers with injection moulding and production suggestions for pallet products, realizing efficient integrated solutions from moulds to finished products.

On working days, we will reply to you within 12 hours of receiving the inquiry.

We are a factory that produces and sells our products with guaranteed quality and favorable prices.

We will conduct corresponding inspections after each process. We will inspect the shipped products according to customer requirements and international standards.

Taizhou Huangyan Jingnan Moulding Co., Ltd. is a private enterprise focusing on the field of moulds and plastic products. As custom Pallet Mould manufacturers and high quality Pallet Mould factory in China, its business scope covers mould sales, plastic product manufacturing and sales, and it has the qualifications for import and export of technology and goods. As an emerging enterprise in the Huangyan mould industry belt, its business layout fits the local industrial advantages of the "Hometown of Chinese Moulds".

Challenges of Complex Geometry in Automotive Components Modern automotive design...

View MoreDefining Design Objectives and Product Characteristics Before detailed engineeri...

View MoreUnderstanding Functional Requirements and Use Scenarios At the early stage of mo...

View MoreIntroduction to Multi-Cavity Mold Design The design of a Plastic Commodity Mold ...

View MoreAs one of the earliest professional manufacturers in China to specialize in pallet mold design and manufacturing, Taizhou Huangyan Jingnan Molding Co., Ltd. has evolved into a leading supplier of pallet molds, leveraging its years of technical expertise and market experience. We consistently adhere to high standards and high efficiency in the development of pallet molds, serving a wide range of industries, including logistics and warehousing, food processing, chemical transportation, and cold chain distribution. Taizhou Huangyan Jingnan Moulding Co., Ltd. manufactures a wide variety of pallet molds, including double-sided pallets, single-sided pallets, nine-legged pallets, grid pallets, flat pallets, and other structures. These pallets meet the needs of heavy-duty, high-turnover industrial applications, as well as economical pallets for one-time export or light handling.

① Precision Mold Design: Taizhou Huangyan Jingnan Moulding Co., Ltd. utilizes advanced CAD/CAM/CAE systems and mold flow analysis technology to ensure uniform filling, smooth demolding, and structural stability during the injection molding process, effectively preventing common problems such as shrinkage and warping.

② Precision Mold Manufacturing: Leveraging extensive manufacturing experience and a rigorous quality control system, Taizhou Huangyan Jingnan Moulding Co., Ltd. ensures that pallet molds achieve industry-leading molding accuracy, mold life, and production efficiency. Our products are exported worldwide. We not only provide mold manufacturing services but also offer OEM and production support for pallet products, providing efficient, integrated solutions from mold to finished product.

③ Injection Molding Capabilities: Taizhou Huangyan Jingnan Moulding Co., Ltd. possesses the ability to develop high-efficiency, multi-cavity injection molds, customizing them to meet customer production requirements and automated production line configurations. We also support in-depth optimization of pallet structures, such as reinforcing ribs, anti-slip surfaces, and slots for RFID or identification cards, to meet the diverse needs of our customers.

④ Material Selection: The pallet molds developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. primarily utilize high-strength mold frame steel and undergo specialized heat treatment processes to enhance mold life and wear resistance.

Manufacturers can expect multiple benefits when partnering with us, which can enhance their business and increase profit margins.

① Professional Technical Elite: Our employees possess a spirit of continuous improvement. From design review to process development, every step is strictly controlled by experienced experts to ensure the optimization of mold structure, the efficiency of cooling systems, and the maximum service life, eliminating potential defects at the source.

② Advanced Science and Technology: Our manufacturing workshop is equipped with advanced equipment such as high-speed precision CNC machining centers, EDM machines, and wire-cut EDM machines. Managed by a digital system, we ensure that every mold core and insert is machined to micron-level precision, guaranteeing high quality and consistency.

③ Competitive Pricing: We offer not the "lowest price," but the "best value for money." Our prices encompass superior design, top-quality materials, precision manufacturing, and reliable service. Choosing us means longer mold life, lower production downtime, and higher product quality, ultimately reducing your total cost of ownership (TCO).

④ Professional After-Sales Service: We offer 24-hour technical hotline support. For any issues with mold use, maintenance, or emergency malfunctions, we promise to provide an initial solution within a specified timeframe, minimizing production disruptions. Our service doesn't end with mold delivery; it begins and ends with delivery, aiming to build a long-term, trustworthy partnership with you.

Pallet Mold Production Solution

① Engineering Verification and Testing (ETV): Focuses on the feasibility of the mold prototype, primarily testing basic structures such as mold base strength and cavity compatibility. Verifies the mold's compatibility with PP/PE raw materials. Initial injection molding process debugging is performed to identify gating and venting issues. A verification report with optimization recommendations and adjusted drawings is produced.

② Design Verification and Testing (DVT): Verifies design integrity based on the ETV optimization solution, inspects cooling and ejection systems, and confirms finished product compatibility through dimensional measurement and load-bearing testing. Equipment compatibility is simulated, and a certificate of conformity and curing design drawings are issued.

③ Production Verification and Testing (PVT): Cures injection molding parameters in a near-production environment, tests production capacity, yield, and production line compatibility, conducts mold durability testing, and produces a production process package containing process specifications and a capacity report to confirm stable production conditions.

④ Mass production: Standardize production according to the PVT process package, conduct sampling inspection every 2 hours, implement equipment maintenance to ensure production capacity, link the supply chain to avoid interruptions, provide after-sales response and optimize the process, and output qualified molds and quality reports.

① Logistics and transportation plastic injection molding pallet molds: As a critical load-bearing tool in industrial logistics systems, pallets place extremely high demands on mold structural stability, load-bearing performance, and molding efficiency. Our mold design fully considers the diverse environments in which pallets are used, supporting custom development of double-sided, nine-legged, grid, and flat pallet configurations. A rational layout of runners and cooling systems not only improves injection molding efficiency but also effectively controls shrinkage and warping of finished products, ensuring dimensional stability and secure stacking. Furthermore, the mold's highly modular structure facilitates maintenance and component replacement, reducing customer operating costs.

② Heavy-duty three-track warehouse plastic pallet molds: Pallets typically feature three longitudinal reinforcing ribs (tracks), making them more stable when used with forklifts, stackers, and racks. They offer excellent resistance to bending, compression, and impact. Our scientifically designed internal cooling system, utilizing a high-thermal-conductivity copper alloy or embedded cooling channels, effectively shortens molding cycles and improves production efficiency. Taizhou Huangyan Jingnan Moulding Co., Ltd. supports custom development in multiple sizes, meeting the stringent dynamic and static load standards of various industries. The mold structure adopts a modular design, facilitating maintenance and part replacement, extending mold life. Through precision manufacturing and strict quality control, Taizhou Huangyan Jingnan Moulding Co., Ltd. provides customers with high-strength, recyclable, and wear-resistant heavy-duty warehouse pallet mold solutions, helping to build an efficient, environmentally friendly, and intelligent logistics system.

③ Stackable Grid Plastic Pallet Injection Mold: The pallet's stackable design and grid drainage structure offer significant practical value, saving space, reducing transportation costs, and keeping goods dry and ventilated, making it highly popular in both domestic and international markets. The precise mold structure and rational design support the molding of pallets in various sizes, nine-legged or double-sided stacking configurations, and can flexibly customize load capacity and stacking height to meet customer needs. Taizhou Huangyan Jingnan Moulding Co., Ltd. has optimized the cooling system, runner layout, and demolding mechanism to significantly improve injection molding cycle efficiency and mold life. Through high-precision manufacturing and strict quality control, Taizhou Huangyan Jingnan Moulding Co., Ltd. helps customers consistently produce lightweight, strong, and reusable mesh pallets in large quantities, contributing to a more environmentally friendly and economical modern logistics supply chain system.

④ Square Hard Plastic Spill-Proof Pallet Crate Mold: The mold features reinforced treatment at the joints and edges between the pallet and crate, effectively preventing liquid leakage and cargo slippage during transportation and stacking, meeting the high safety standards of the food, chemical, and pharmaceutical industries. The mold's optimized internal flow channels and cooling system layout ensure uniform filling during the injection molding process, minimizing shrinkage and deformation. The mold also supports a multi-cavity design and modular construction, facilitating interchangeable pallet and crate assemblies of varying specifications and styles to meet diverse customer customization needs. Leveraging advanced processing equipment and rigorous quality control, Taizhou Huangyan Jingnan Moulding Co., Ltd. provides customers with high-efficiency, high-precision, and long-life square hard plastic spill-proof pallet and crate molds, helping to achieve safe and reliable logistics, transportation, and storage solutions.

① Logistics and Transportation Plastic Injection Pallet Mold: Taizhou Huangyan Jingnan Moulding Co., Ltd. boasts mature pallet mold design and manufacturing capabilities. We utilize high-strength mold steel, coupled with advanced mold flow analysis and CNC precision machining, to ensure that pallets resist deformation under heavy loads and possess excellent pressure and impact resistance.

② Heavy-Duty Three-Rail Warehouse Plastic Pallet Mold: Taizhou Huangyan Jingnan Moulding Co., Ltd. utilizes high-standard mold steel, specifically designed for the structural characteristics of heavy-duty three-rail pallets. Integrating CAE mold flow analysis with 3D mechanical structural design, this ensures the mold maintains structural stability even under high-tonnage injection molding machines. The resulting molded pallet is subjected to balanced forces and resists deformation.

③ Stackable Grid Plastic Pallet Injection Mold: Taizhou Huangyan Jingnan Moulding Co., Ltd. integrates multiple technological advantages in the design and manufacturing of this type of mold. We utilize high-strength mold steel, coupled with mold flow analysis systems and 3D structural simulation technology, to ensure uniform stress distribution, consistent wall thickness, and resistance to warping and cracking during the injection molding process.

④ Square hard plastic anti-spill pallet crate mold: Taizhou Huangyan Jingnan Moulding Co., Ltd. focuses on structural rigidity and sealing when designing this type of mold. Thickened ribs and a reasonable wall thickness distribution are used to enhance the overall strength and impact resistance of the pallet and crate. The anti-spill edge design is sophisticated, and the edge height and inclination angle are scientifically calculated to effectively intercept liquids while ensuring stacking stability.

① Logistics and Transportation Plastic Injection Pallet Molds are high-strength injection molds specifically developed for producing plastic pallets used in warehousing, transportation, handling, and export logistics. They are widely used in automated warehousing, logistics, and transportation, cold chain distribution, and overseas exports, helping customers build efficient, environmentally friendly, and recyclable logistics systems.

② Heavy-Duty Three-Rail Warehouse Plastic Pallet Molds are injection molds designed for producing high-strength, high-load-bearing three-rail plastic pallets. They are widely used in three-dimensional warehousing systems, automated logistics, cold chain transportation, and heavy-load cargo stacking operations.

③ Stackable Grid Plastic Pallet Molds are specially designed for producing grid-type plastic pallets with a lightweight structure, good ventilation, and convenient storage and transportation. They are widely used in warehousing, transportation, and export logistics in industries such as food, pharmaceuticals, electronics, light industry, and chemicals.

④ Square Hard Plastic Spill-Proof Pallet Crate Molds are designed for producing strong, durable, and spill-proof plastic pallets and crates. This type of mold has been reinforced for the joints and edges between pallets and crates, ensuring effective prevention of liquid leakage and cargo slippage during transportation and stacking, meeting the high standards of safety protection required by industries such as food, chemicals, and pharmaceuticals.