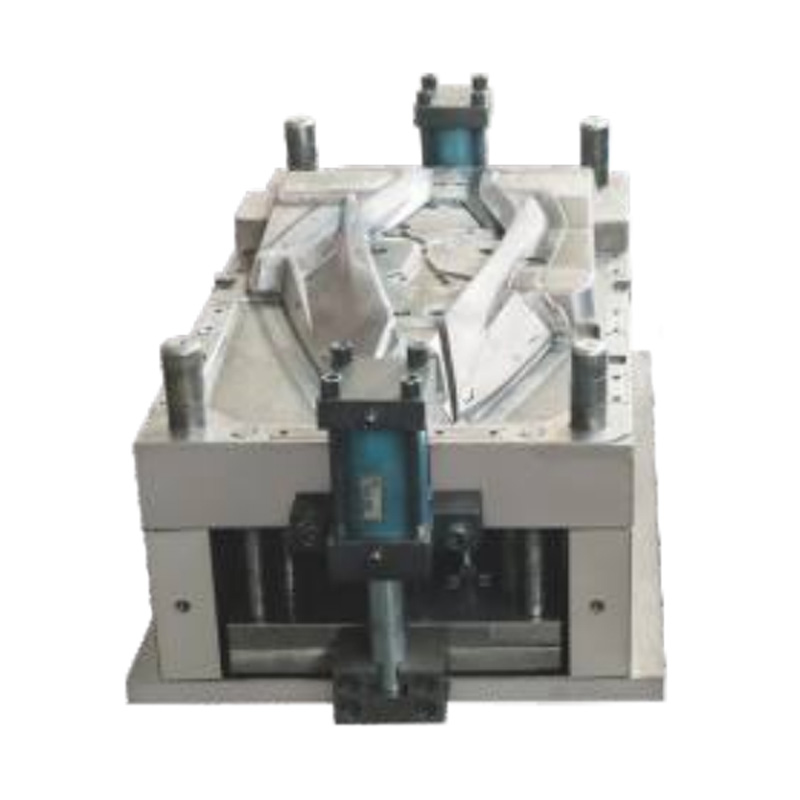

Motorcycle parts molds are a key type of mold in the motorcycle manufacturing process, involving engine hoods, frame guards, instrument panels, fuel tank caps, side covers and other important parts. Jingnan Mold has been deeply involved in this field. With rich design experience and advanced manufacturing equipment, it can tailor high-precision and high-durability motorcycle parts molds for customers. Such molds usually require compact structure, precise size, good heat resistance and impact resistance to meet the strict performance requirements of motorcycles in high-speed operation and complex environments.

Jingnan Mold uses imported high-quality mold steel, combined with precision machining and strict heat treatment process to ensure that the mold has excellent mechanical strength and service life. At the same time, we use advanced CAD/CAM design and mold flow analysis technology to optimize the mold structure and injection molding process, reduce deformation and residual stress, and improve the surface quality and dimensional stability of molded parts. In response to the diverse appearance design requirements of motorcycle parts, Jingnan Mold also pays special attention to product detail processing and assembly coordination to ensure the efficiency and consistency of mold mass production.

With a professional technical team and a complete quality management system, Jingnan Mould provides motorcycle manufacturers with reliable mould solutions, helping customers improve product competitiveness and market response speed, and becoming a trustworthy partner in the field of motorcycle parts moulds.

On working days, we will reply to you within 12 hours of receiving the inquiry.

We are a factory that produces and sells our products with guaranteed quality and favorable prices.

We will conduct corresponding inspections after each process. We will inspect the shipped products according to customer requirements and international standards.

Taizhou Huangyan Jingnan Moulding Co., Ltd. is a private enterprise focusing on the field of moulds and plastic products. As custom Motorcycle Parts Mould manufacturers and high quality Motorcycle Parts Mould factory in China, its business scope covers mould sales, plastic product manufacturing and sales, and it has the qualifications for import and export of technology and goods. As an emerging enterprise in the Huangyan mould industry belt, its business layout fits the local industrial advantages of the "Hometown of Chinese Moulds".

Challenges of Complex Geometry in Automotive Components Modern automotive design...

View MoreDefining Design Objectives and Product Characteristics Before detailed engineeri...

View MoreUnderstanding Functional Requirements and Use Scenarios At the early stage of mo...

View MoreIntroduction to Multi-Cavity Mold Design The design of a Plastic Commodity Mold ...

View MoreMotorcycle molds are a key mold type in the motorcycle manufacturing process, encompassing key components such as engine hoods, frame guards, instrument panels, fuel tank caps, and side covers. Taizhou Huangyan Jingnan Moulding Co., Ltd., with extensive design experience and advanced manufacturing equipment, can tailor-make high-precision, high-durability motorcycle molds for our customers.

① Precision Machining Capabilities: We utilize an integrated CAD/CAM design system, using UG and AutoCAD software for 3D modeling and process simulation to proactively mitigate interference risks. We incorporate in-process inspection systems (such as Renishaw probes) to compensate for tool wear errors in real time. Finished product inspection relies on coordinate measuring machines (such as the Zeiss CONTURA G2) for full-scale inspection of critical mold dimensions (such as locating hole spacing and cavity depth), ensuring tolerances within ±0.005mm and meeting motorcycle component assembly clearance requirements (typically ≤0.1mm).

② Cooling System Capability: Optimizing the cooling system can effectively shorten molding cycles and improve production efficiency. The finished product has a smooth, warp-free surface, a strong structure, strong impact resistance, excellent durability, and protective properties, adapting to various complex road and climate environments.

③ Injection Molding Process Capability: Select the injection molding machine based on the part type: Use a suitable large machine for large exterior parts (to avoid surface streaks), a high-precision machine for fine small parts, and a machine with precise temperature control for heat-resistant parts.

Auxiliary Tools: Use equipment to dry the material (to reduce moisture), remove excess air from the mold (to avoid bubbles in the part), and cool the mold in different zones (to prevent part deformation).

④ Material selection: Mold materials are matched to the properties of the plastic part. For example, when molding corrosive plastics like PVC, the mold cavity surface needs to be chrome-plated (thickness 5-10μm) or corrosion-resistant steel 2083 (DIN 1.4305). All materials meet ISO 9001 quality standards and are accompanied by material certificates when purchased. Before storage, components are tested using a spectrometer (such as the SPECTROMAXx) to prevent inferior materials from entering production.

Manufacturers can expect multiple benefits when partnering with us, which can enhance their business and increase profit margins.

① Extensive Design Experience: Taizhou Huangyan Jingnan Moulding Co., Ltd. utilizes 3D modeling and mold flow analysis technology to ensure that complex instrument covers and suspension structures are filled and vented smoothly during the injection molding process, effectively preventing defects such as bubbles, deformation, and short shots. Through 3D modeling and mold flow analysis, we optimize the layout of gates, runners, and cooling systems, ensuring uniform molding of thin-walled, complexly curved fairings without warping or deformation, resulting in a high surface finish that is ready for spraying or screen printing. Mold flow analysis also optimizes gate location and cooling systems, ensuring that injection molded parts are free of warping, deformation, and shrinkage, improving the yield rate of finished products.

② Application Advantages: Taizhou Huangyan Jingnan Moulding Co., Ltd. efficiently molds fuel tank caps with smooth curves and strong structural seals. This not only achieves a uniform aesthetic but also ensures a tight opening and closing, smooth operation, and excellent dust and water resistance. For components that are frequently used on motorcycles, Taizhou Huangyan Jingnan Moulding Co., Ltd. places extremely high demands on dimensional accuracy and durability. Other components not only enhance the overall vehicle's appearance but also utilize airflow guidance to reduce wind resistance, improve driving stability, reduce fuel consumption, and protect the driver from wind, sand, and rain.

③ Customizable Products: Taizhou Huangyan Jingnan Moulding Co., Ltd. supports personalized customization to meet the diverse demands for exterior styling and functionality across different vehicle models. We support customization in a variety of colors and surface finishes (such as matte, glossy, and textured) to meet the differentiated appearance needs of different brands. We also offer customized fuel tank cap designs, textures, and snap-fit mechanisms based on vehicle model requirements, helping customers create differentiated products and enhance brand recognition. We also support personalized mold development based on vehicle size, tire specifications, mounting methods, and brand style. Whether it's a sports, off-road, or urban commuter motorcycle, we offer customizable fender designs, including full-cover, semi-cover, streamlined, or split configurations. We can also customize features like brand logo inserts, decorative strip slots, and screw posts to create a unique product solution.

④ Professional Team: Taizhou Huangyan Jingnan Moulding Co., Ltd. provides integrated solutions from product design evaluation, mold development, trial molds, and mass injection molding. Equipped with advanced injection molding equipment and precise process control systems, we ensure that every product achieves a smooth surface, crisp contours, and a stable structure, meeting the stringent tolerances required for motorcycle assembly. Leveraging our professional molding technology and rigorous quality control processes, we provide customers with high-quality, fast-delivery, and flexible injection molding services, helping them create competitive motorcycle exterior and structural parts. With our professional manufacturing experience and efficient delivery services, we offer reliable, high-quality, complete solutions for motorcycle fuel tank cap injection molds.

① Engineering Verification and Testing (ETV): This is the initial stage of mold production. It primarily checks whether the mold's basic design meets the essential requirements of motorcycle parts, such as the mold's material strength and overall structural support for subsequent processing. A simple assembly test is also performed to identify issues such as poor part fit and basic dimensional deviations, ensuring the mold's feasibility for production from an engineering perspective.

② Design Verification and Testing (DVT): This stage focuses on the rationality and practicality of the mold design. Actual production scenarios are simulated to test the mold's detailed design for usability, such as whether the part's molding grooves and demolding mechanisms enable smooth product production and prevent issues such as material sticking and deformation. Through repeated adjustments to design details, the mold is ensured to meet product specifications and conform to production operational procedures.

③ Production Verification and Testing (PVT): This phase begins with small-scale pilot production. The mold is used to produce small batches of parts, focusing on its stability during continuous operation, such as ensuring production efficiency meets standards and consistent part quality. The mold is also inspected for wear and failure after repeated use, allowing for timely adjustments and optimization to clear obstacles for mass production. ④ Mass Production: After the first three rounds of validation, the mold officially enters the large-scale production phase. A stable production line is established to ensure the continuous and efficient operation of the mold. Dedicated personnel are assigned to regularly maintain the mold and monitor part production quality to ensure that the motorcycle parts produced meet standards in terms of quantity, precision, and durability to meet mass supply requirements.

① Motorcycle Body Frame Plastic Mold: This mold design emphasizes structural rigidity and precision, ensuring dimensional stability and precise fit of the molded part. This improves the assembly accuracy and overall strength of the body frame, enhancing the motorcycle's safety and service life. The mold's optimized flow channel and cooling system layout ensure uniform plastic melt filling of thin-walled, complex structures, preventing shrinkage, warping, and porosity defects, and improving yield and appearance quality.

② Motorcycle Instrument Cover Suspension Injection Mold: This mold requires smooth shaping, precise dimensions, and reliable strength, while also possessing excellent heat and shock resistance to accommodate complex and changing riding environments.

③ Motorcycle Fuel Tank Cap Plastic Injection Mold: This mold boasts stable molding, a rational structure, and high production efficiency, meeting the dual requirements of vehicle manufacturers for both aesthetics and functionality.

④ Motorcycle Fairing Kit Plastic Mold: This high-performance mold, developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. specifically for motorcycle exterior design and wind resistance control, is suitable for injection molding complete vehicle fairing components, including front, side, and tail cowls, wind deflectors, and other components.

⑤ Motorcycle Tail Seat Side Cover Plastic Mold: This mold's surface treatment allows for secondary processing such as high gloss, painting, and decals, meeting the aesthetic requirements of various brands and models.

⑥ Motorcycle Fender Plastic Accessory Mold: The finished product features a smooth, warp-free surface, a strong structure, and strong impact resistance, offering excellent durability and protective properties, suitable for a variety of complex road and climate environments.

① Motorcycle body frame plastic mold: This mold utilizes high-strength mold steel, combined with advanced CNC machining and heat treatment processes, ensuring high mold hardness, wear resistance, and long life. It can meet high-volume production needs and reduce customers' long-term costs.

② Motorcycle instrument cover suspension injection mold: This mold is constructed from high-hardness, corrosion-resistant material and undergoes high-precision CNC machining and heat treatment to extend mold life and maintain long-term dimensional stability.

③ Motorcycle fuel tank cap plastic injection mold: This mold utilizes high-quality mold steel and undergoes precision CNC machining and polishing to achieve a smooth and flawless surface, meeting customer requirements for post-processing such as high gloss, spray painting, and silk screen printing.

④ Motorcycle fairing kit plastic mold: This mold utilizes high-strength mold steel, combined with high-precision CNC machining, polishing, and heat treatment processes to ensure wear resistance, corrosion resistance, and long life.

⑤ Motorcycle tailgate side cover plastic mold: This mold has a stable structure and is made from high-quality mold steel, offering excellent wear resistance and service life, making it suitable for long-run, high-volume production.

⑥Motorcycle fender plastic accessories mold: This mold is made of high-quality mold steel, combined with five-axis CNC precision machining and mold flow simulation analysis technology to ensure a reasonable mold structure, scientific gate design, smooth filling, and clean demolding during the injection molding process.

① Motorcycle Body and Frame Plastic Molds: As key component molds specialized by Taizhou Huangyan Jingnan Moulding Co., Ltd., motorcycle body and frame plastic molds offer multiple advantages, helping customers produce high-quality, high-performance motorcycle plastic parts.

② Motorcycle Instrument Cover Suspension Injection Molds: These are key mold types custom-developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. for high-precision molding of motorcycle plastic parts. They are primarily used to produce key exterior and functional components such as instrument covers and front suspension guards.

③ Motorcycle Fuel Tank Cap Plastic Injection Molds: Developed by Taizhou Huangyan Jingnan Moulding Co., Ltd., these high-precision mold solutions are specifically designed for fuel tank cap components on two-wheeled vehicles. They are widely used in exterior decoration and sealing structures for various motorcycles, scooters, and off-road vehicles.

④ Motorcycle Fairing Kit Plastic Mold: Motorcycle fairing kit plastic molds are widely used in a variety of models, including scooters, sports cars, and cruisers. Their advantages lie in precise molding, stable structure, and attractive appearance, effectively enhancing the motorcycle's overall performance and visual recognition.

⑤ Motorcycle Tail Seat Side Cover Plastic Mold: This high-precision injection mold was developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. specifically for motorcycle rear covers. It is primarily used to produce the plastic shell that wraps around the sides of the tail seat, providing both protective functionality and decorative effects.

⑥ Motorcycle Fender Plastic Accessory Mold: This is a key injection mold product developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. specifically for the driving environment of two-wheeled vehicles. It is widely used above the front and rear tires, playing a key role in blocking mud and water splashes and protecting the vehicle body and the driver.