Jingnan Mould focuses on the research and development and manufacturing of automotive parts moulds, and always adheres to the concept of stable product quality. From design, manufacturing, testing to management, every process and every link are strictly controlled to ensure that the performance of the mould is consistent with the quality of the mould. We are well aware of the high standards of mould accuracy, durability and consistency for automotive parts. Therefore, in the process of mould development, we combine advanced CAD/CAM/CAE technology for structural optimization and mould flow analysis, which greatly improves the stability and moulding effect of the mould.

Jingnan Mould uses high-quality mould steel, combined with strict heat treatment process and precision machining equipment to ensure that each set of automotive parts mould has excellent wear resistance and strength, and meets the strict regulations of the automotive industry for safety and reliability. At the same time, we pay attention to the convenience and efficiency of mould maintenance, and reduce the cost of later use and improve customer production efficiency through reasonable structural design and standardized accessories application.

Adhering to the service concept of quality first and customer first, Jingnan Mould is committed to providing customers with more advanced, more reasonable and more precise automotive parts mould solutions, helping customers gain advantages in the fierce market competition and create high-quality automotive parts products.

On working days, we will reply to you within 12 hours of receiving the inquiry.

We are a factory that produces and sells our products with guaranteed quality and favorable prices.

We will conduct corresponding inspections after each process. We will inspect the shipped products according to customer requirements and international standards.

Taizhou Huangyan Jingnan Moulding Co., Ltd. is a private enterprise focusing on the field of moulds and plastic products. As custom Automotive Parts Mould manufacturers and high quality Automotive Parts Mould factory in China, its business scope covers mould sales, plastic product manufacturing and sales, and it has the qualifications for import and export of technology and goods. As an emerging enterprise in the Huangyan mould industry belt, its business layout fits the local industrial advantages of the "Hometown of Chinese Moulds".

Challenges of Complex Geometry in Automotive Components Modern automotive design...

View MoreDefining Design Objectives and Product Characteristics Before detailed engineeri...

View MoreUnderstanding Functional Requirements and Use Scenarios At the early stage of mo...

View MoreIntroduction to Multi-Cavity Mold Design The design of a Plastic Commodity Mold ...

View MoreTaizhou Huangyan Jingnan Moulding Co., Ltd. specializes in the research, development, and manufacturing of automotive molds, adhering to a philosophy of consistent product quality. From design, manufacturing, testing, and management, every process and every link is rigorously controlled to ensure consistent mold performance and molding quality. We are deeply aware of the high standards for mold precision, durability, and consistency required for automotive parts. Therefore, during mold development, we incorporate advanced CAD/CAM/CAE technologies for structural optimization and mold flow analysis, significantly improving mold stability and molding results. Taizhou Huangyan Jingnan Moulding Co., Ltd. utilizes high-quality mold steel, coupled with rigorous heat treatment processes and precision machining equipment, to ensure that each automotive mold possesses excellent wear resistance and strength, meeting the automotive industry's stringent safety and reliability standards. We also prioritize convenient and efficient mold maintenance. Through rational structural design and the use of standardized accessories, we reduce ongoing operating costs and improve our customers' production efficiency. Adhering to the service philosophy of prioritizing quality and customer satisfaction, Taizhou Huangyan Jingnan Moulding Co., Ltd. is committed to providing customers with more advanced, rational, and precise automotive mold solutions, helping them gain an advantage in the fiercely competitive market and create high-quality automotive parts.

① Core Manufacturing Capabilities: Taizhou Huangyan Jingnan Moulding Co., Ltd. utilizes 3D CAD modeling and mold flow analysis software to simulate filling, holding, cooling, and demolding in the early stages of product development. This ensures optimal gate placement and uniform flow without short shots, air marks, or deformation.

② Key Supporting Technologies: Taizhou Huangyan Jingnan Moulding Co., Ltd. prioritizes mold cooling system design, employing multi-point channels and a uniform water channel layout to improve cooling efficiency, shorten molding cycles, and ensure uniform wall thickness and a smooth surface for each finished part. The mold structure supports quick-change inserts and a split demolding mechanism, facilitating maintenance and rapid commissioning, enhancing production flexibility.

③ Industry Adaptability Requirements: Taizhou Huangyan Jingnan Moulding Co., Ltd.'s cooling system layout is scientifically designed to effectively improve injection molding efficiency and minimize deformation risks. The mold structure supports the integration of functional areas such as the vehicle logo insert, radar aperture, and air damper grille, enhancing component practicality and expanding intelligent capabilities. The mold parting surface is streamlined along the overall contour of the bumper, ensuring a smooth surface finish and high assembly precision while also facilitating uniform melt flow and filling during the injection molding process. A quick-change mechanism at the bottom of the mold allows for rapid replacement or adjustment of structural components, facilitating subsequent product modifications and the addition of sports kits, significantly enhancing the mold's versatility and maintainability.

④ Structural System Support: Taizhou Huangyan Jingnan Moulding Co., Ltd.'s modular design facilitates ongoing maintenance and minor modifications. As a professional mold manufacturer, Taizhou Huangyan Jingnan Moulding Co., Ltd. not only provides one-stop services from structural design, mold trial commissioning, and injection molding technical support, but also offers rapid response and customized solutions tailored to the customer's vehicle platform, ensuring efficient project execution. At the same time, we provide one-stop services from product structure optimization, mold manufacturing, to mold trial verification, ensuring that customers can obtain high-precision, high-transparency, and high-stability mold support when developing LED headlight plastic housing products.

Manufacturers can expect multiple benefits when partnering with us, which can enhance their business and increase profit margins.

① Pursuing High Product Quality: Taizhou Huangyan Jingnan Moulding Co., Ltd. fully considers the bumper's stress-bearing areas, mounting clips, energy-absorbing ribs, and other structural details in its design. Through mold flow analysis, we precisely optimize the gate and cooling system layout to ensure rapid and uniform mold filling of the plastic melt, avoiding common defects such as deformation, shrinkage, and short shots.

② Meeting Customer Requirements: Taizhou Huangyan Jingnan Moulding Co., Ltd. offers a complete custom development process, enabling customized designs tailored to different vehicle platforms and bumper structural requirements. We support simultaneous mold development for multiple styles, improving customer product updates. We also provide comprehensive services, including mold commissioning, injection molding trials, sample verification, and mold maintenance, ensuring efficient production upon mold delivery. Taizhou Huangyan Jingnan Moulding Co., Ltd. offers customized grille designs to meet the rapid update needs of different models and markets, providing customers with high-quality, differentiated automotive exterior solutions. Leveraging its extensive experience in automotive interior molds and comprehensive quality management systems, Taizhou Huangyan Jingnan Moulding Co., Ltd. provides customers with highly reliable, high-precision, and efficient complete mold solutions.

③ Professional Technical Support: Taizhou Huangyan Jingnan Moulding Co., Ltd. utilizes 3D CAD modeling and mold flow analysis technology, combining the structural characteristics and assembly requirements of headlights to precisely control the flow direction and thickness distribution in the optical lens area. This ensures high transparency, a surface free of flow marks, ripples, or bubbles, and meets high optical performance standards for injection molded parts.

④ High-Demand System Feedback: Taizhou Huangyan Jingnan Moulding Co., Ltd.'s cooling system is rationally designed and utilizes a highly efficient circulating water system to improve production efficiency and shorten molding cycles.

① Engineering Verification and Testing (ETV): This is the initial inspection step in automotive mold production. This phase primarily verifies whether the mold's basic design meets the requirements of different automotive parts. For example, body parts and interior parts require different mold material hardness and overall structure. Simple tests are conducted to verify the accuracy of the mold's basic dimensions and the initial compatibility of its components, ensuring the mold meets the basic engineering requirements for automotive part production.

② Design Verification and Testing (DVT): This phase focuses on practical debugging of the mold design. Actual automotive part production scenarios are simulated to verify the rationality of the mold's detailed design. For example, the smooth molding grooves of curved interior parts and the ease of demolding of metal structural parts are tested to avoid problems such as product sticking and deformation. This ensures that the mold design meets automotive part specifications and is easy to operate in actual production.

③ Production Verification and Testing (PVT): This phase begins with the verification phase of small-scale pilot production. The mold is used to produce a small batch of automotive parts, focusing on observing the mold's stability during continuous operation, ensuring that production efficiency meets standards, and that the quality of the parts produced is consistent. The mold is also inspected for wear and failure after repeated use, allowing for timely adjustments and optimization to prepare for subsequent large-scale production.

④ Mass Production: After the first three rounds of rigorous verification, the mold officially enters the large-scale production phase. We will build an assembly line that meets the needs of mass production of automobiles, ensure the continuous and efficient operation of the molds, arrange dedicated personnel to regularly maintain the molds, monitor the accuracy and durability of the produced parts in real time, ensure that they meet automobile manufacturing standards, and meet the mass supply needs of automobile companies.

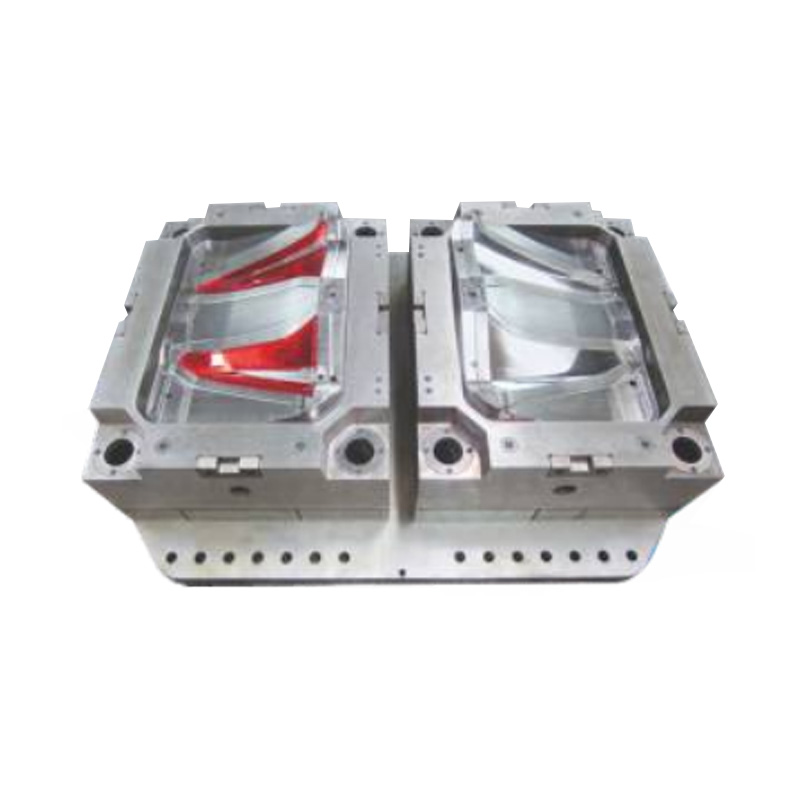

① Durable Automotive Bumper Injection Molds: Molded parts have high dimensional consistency and excellent strength, allowing for direct post-processing such as painting, electroplating, and decorative inserts.

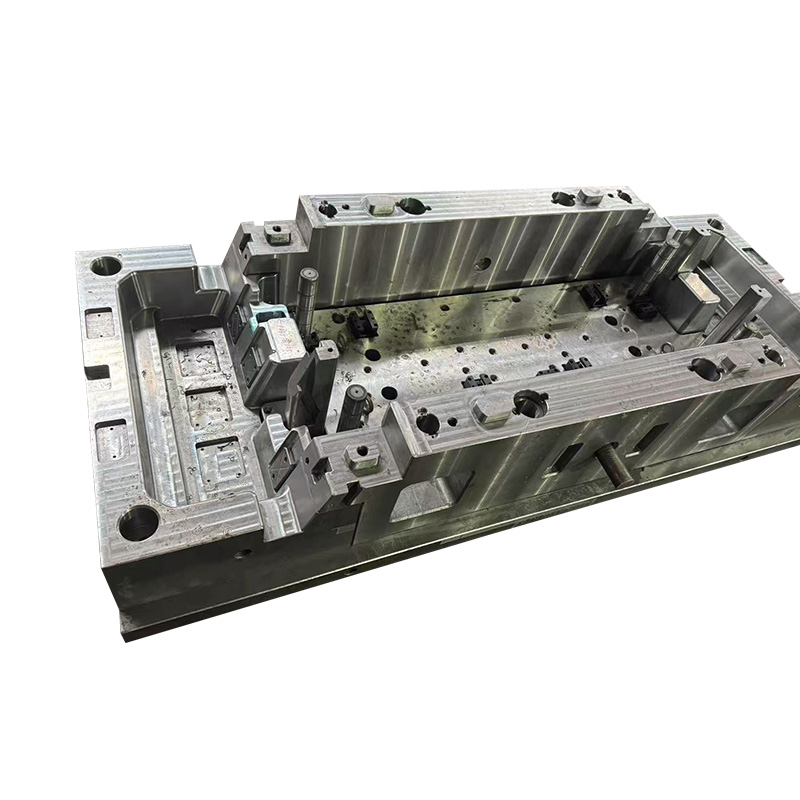

② Automotive Door Trim Panel Plastic Injection Molds: The molds are complex, large, and require extremely high surface finishes and precise design.

③ Front Grille Replacement Molds: Customizable cavity structures tailored to the grille size and styling of different vehicle models (e.g., sports and business models) ensure the molded replacement parts precisely match the original vehicle dimensions, with surface textures and mounting hole locations meeting assembly requirements.

④ Automotive Cockpit Interior Instrument Panel Injection Molds: Customizable surface curvature and hole location based on the cockpit layout to accommodate the installation requirements of instruments, buttons, and other components. Adjustable injection molding parameters ensure a smooth, sink-free instrument panel surface.

⑤ Automotive LED Headlamp Plastic Housing Mold: The mold's sophisticated structural design supports multiple parting and core-pulling mechanisms, meeting the molding requirements of complex three-dimensional headlight structures and ensuring precise assembly of the lamp housing and body.

⑥ Large Single-Cavity Automotive Bumper Injection Mold: The mold features a large single-cavity design and can be adapted for front or rear bumper production, meeting the platform-based manufacturing requirements of multiple vehicle models.

① Durable Automotive Parts Bumper Injection Mold: The mold is constructed from high-strength mold steel and precision-machined using a large gantry CNC machining center and five-axis equipment. This ensures a sturdy mold structure and a high-quality mold cavity finish, meeting the requirements of long-run, high-volume production.

② Automotive Door Trim Panel Plastic Injection Mold: The mold is constructed from high-standard steel with excellent wear resistance and thermal conductivity. ③ Front Grille Replacement Injection Mold: The mold is constructed from high-quality mold steel, combined with precision CNC machining and mold flow analysis to ensure a stable mold structure, precise part dimensions, and a clear, full-bodied appearance, meeting Hyundai's high requirements for visual impact and brand recognition for front fascias.

④ Automotive Cockpit Interior Instrument Panel Injection Mold: The mold is manufactured using high-quality steel, combined with five-axis CNC machining and mold flow analysis to ensure cavity accuracy and surface finish. Optimized gate and cooling system design achieves high-standard injection molding results with uniform thickness and zero deformation.

⑤ Automotive LED Headlamp Plastic Housing Mold: The mold is constructed from high-standard mold steel and undergoes polishing and mirror finishing to achieve a mirror-like surface finish, effectively improving the finish and light transmittance of transparent plastic parts.

⑥ Large Single-Cavity Automotive Bumper Injection Mold: The mold is constructed from high-strength mold steel and precision machining, combined with an optimized cooling waterway layout to ensure dimensional stability, surface quality, and production efficiency during mass production.

① Durable Auto Parts Bumper Injection Mold: This durable auto parts bumper injection mold is a large, high-strength, high-precision mold developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. specifically for front and rear bumper components. It is widely used in the exterior protection systems of sedans, SUVs, commercial vehicles, and other models.

② Automotive Door Trim Panel Plastic Injection Mold: This large, high-precision injection mold developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. is designed for interior door trim. It is primarily used to produce cover panels and functional decorative parts on the inside of passenger car doors.

③ Front Grille Replacement Part Injection Mold: This high-precision mold was developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. specifically for the automotive exterior trim market. It is primarily used to produce upgrades or replacement front grilles for various vehicle models, serving a wide range of OEM, aftermarket, and automotive modification industries.

④ Automotive Cockpit Interior Instrument Panel Injection Mold: This large, complex mold is specially developed by Taizhou Huangyan Jingnan Moulding Co., Ltd. specifically for the entire vehicle interior system. It is primarily used to mold the cockpit center console assembly, encompassing key structures such as the instrument panel body, air vents, function button area, and airbag openings.

⑤ Automotive LED Headlamp Plastic Housing Mold: This important mold product, developed by Taizhou Huangyan Jingnan Moulding Co., Ltd., specifically for modern automotive lighting systems, is primarily used to mold the transparent headlight shade and inner shell structure of the headlight, a key component for the vehicle's aesthetic appearance and safety lighting performance.

⑥ Large Single-Cavity Automotive Bumper Injection Mold: This large single-cavity auto bumper injection mold is widely used in the manufacture of passenger and commercial vehicle bodies. The cavity's curved surface profile and reinforcing rib structure can be customized according to the vehicle model, ensuring the bumper's dimensional accuracy and impact resistance, and meeting the vehicle's appearance and protection requirements.