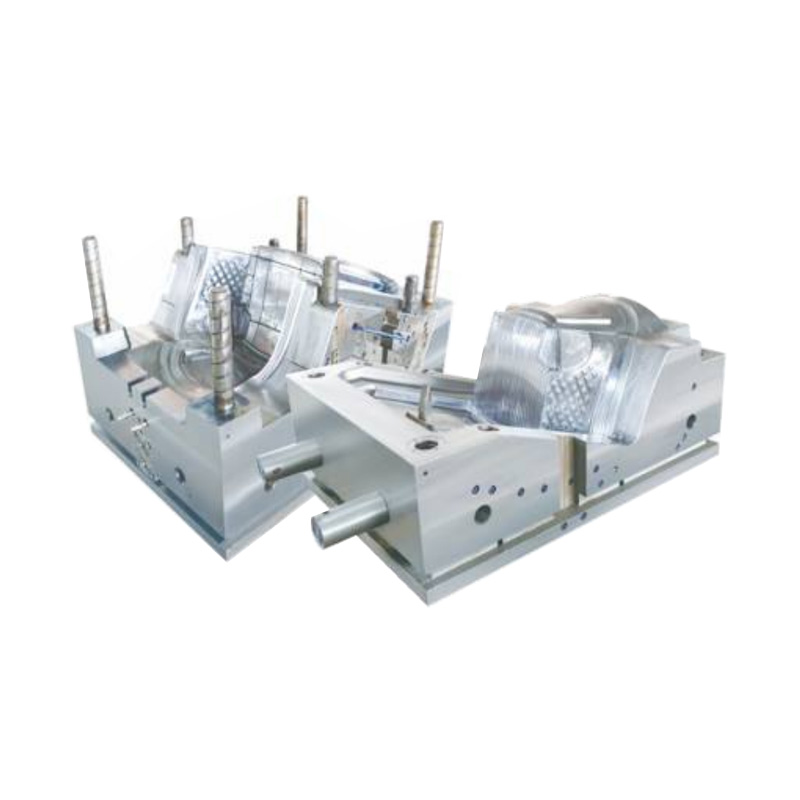

Industrial Air Cooler Plastic Mold

As an OEM factory specializing in the design and manufacture of air co...

The design of a Plastic Chair Mold is closely influenced by the intended structure and geometry of the chair, much like how pallet designs vary. Different structural patterns—such as solid bases, rib-reinforced seats, or perforated frameworks—require distinct mold engineering strategies to ensure durability, aesthetics, and efficient production. Understanding these differences is crucial for manufacturers aiming for high-quality chairs with minimal defects.

• Solid chair bases, often used for indoor seating, require molds that allow uniform filling of large, thick sections.

• Cooling channels need careful placement to prevent warping and sink marks, as thick areas retain heat longer.

• Ejector pin layouts must ensure the solid surface can be removed cleanly without scratching or deforming the chair.

• Chairs with ribs or webbing are lighter and maintain strength. The mold must account for thinner walls combined with reinforcing ribs.

• Flow analysis becomes critical to ensure the melt reaches all cavities and avoids air traps in rib intersections.

• Runner and gate placement must balance filling between thick rib zones and thinner areas to maintain uniform density.

• Mold design for chairs with perforations or holes requires precise attention to venting and flow.

• These designs prevent heat buildup and reduce material usage but increase the complexity of flow paths.

• Specialized cores or inserts are often needed to shape holes without compromising surface quality or causing flash.

• Different structures create non-uniform wall thicknesses. The Plastic Chair Mold must accommodate this variation to avoid warping and incomplete filling.

• Higher injection pressures may be necessary for dense or ribbed structures, while delicate perforated designs require lower pressures to avoid burn marks and degradation.

• Strategic gate locations ensure uniform melt distribution. For ribbed or perforated chairs, multiple gates or hot runner systems may be employed to maintain consistent quality.

Cooling System Design Differences

• Solid sections need robust cooling channels close to the surface to prevent long cycle times.

• Ribbed or perforated areas require channels that avoid obstructing ribs or inserts, balancing cooling efficiency without causing hotspots.

• Properly designed cooling systems reduce internal stress and warpage across various chair structures, ensuring dimensional stability and aesthetic quality.

Ejection and Mold Maintenance

• Straightforward ejector pin arrangements work well for solid bases, reducing wear.

• Ribbed or perforated chairs often require additional lifters, slides, or core pulls to release complex features without damaging the mold or chair.

• Regular maintenance is essential to prevent deformation of the thin rib or perforation sections during repeated cycles.

Different chair structures significantly influence Plastic Chair Mold design. Solid, rib-reinforced, and perforated chairs each present unique challenges in terms of material flow, cooling, gate placement, and ejection. By carefully analyzing the intended structure, mold designers can optimize production efficiency, reduce defects, and deliver high-quality chairs that meet strength, aesthetics, and durability standards. Proper mold design ensures consistent performance across diverse chair geometries, enabling manufacturers to adapt to market demands and innovative product designs.