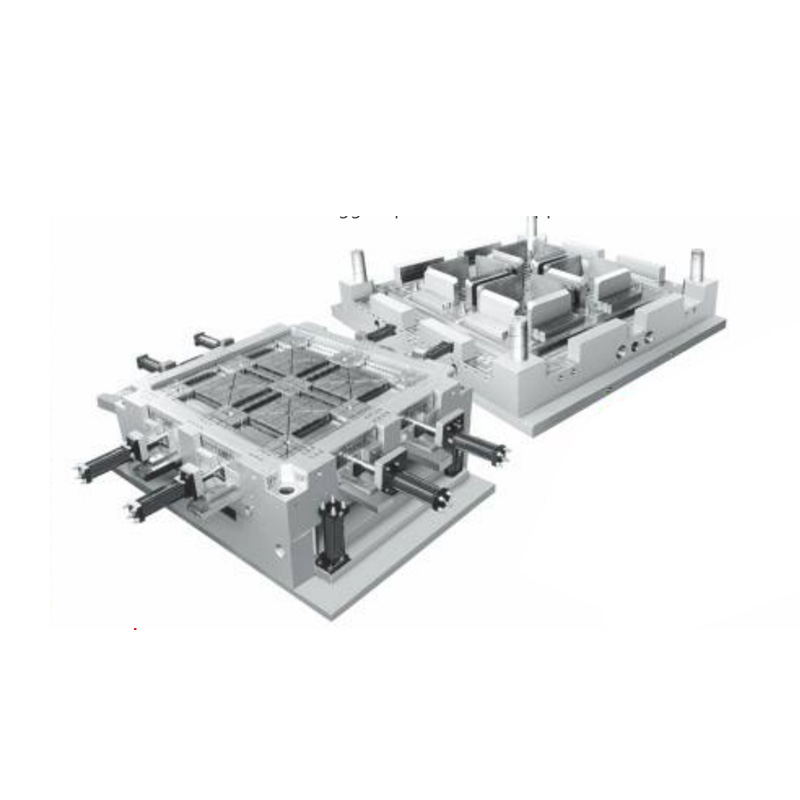

Household Appliance Air Cooler Mold

From the perspective of household appliance mold manufacturing, househ...

The structural design of a Plastic Pallet Mold directly determines how molten plastic enters, flows, and fills the cavity. Gate placement is one of the influential factors affecting balance, strength, and surface quality during injection molding.

The gate determines the starting point of plastic flow. If positioned too close to thick sections, the melt may cool unevenly, causing short shots or swirl marks. A centrally located gate often promotes symmetrical flow, particularly for large pallet designs.

Uneven gate placement causes differences in packing pressure across the pallet. Areas farther from the gate receive less pressure, resulting in uneven shrinkage. This imbalance can cause warping, corner lifting, or deformation.

Oversized gates allow excessive melt flow, increasing the risk of flashing. Undersized gates create high shear rates, potentially degrading plastic material and reducing mechanical strength in certain pallet regions.

The runner system connects the plastic injection point to the mold cavity. Its geometry and balance significantly influence the molding uniformity of large pallet structures.

A balanced runner system ensures equal distance and pressure from the sprue to all cavity sections. In large pallet molds, unbalanced runners cause partial overpacking on one side and insufficient filling on the other.

Full-round or trapezoidal runners maintain a more stable melt temperature compared with rectangular runners. Stable temperature profiles help prevent cold spots, flow hesitation, and weld lines.

Longer runners increase resistance and pressure loss, reducing melt flow to distant areas. Strategic optimization is necessary to ensure uniform pressure at all points, particularly for pallets with thick ribs or structural frames.

Gate and runner performance cannot be evaluated independently. Their interaction defines the final filling behavior of the mold.

Proper integration ensures that molten plastic reaches all critical points at the same time. When synchronized, weld lines are reduced, and mechanical strength becomes more uniform across the pallet.

Poorly aligned runners and gates can cause stagnant flow zones where plastic cools prematurely. These areas typically exhibit weak bonding, flow marks, or incomplete cavity filling.

A well-designed system maintains consistent packing pressure to decrease sink marks in rib structures and top deck patterns.

Manufacturers employ several engineering methods to enhance the uniformity of injection molding for pallet production.

This helps distribute the melt evenly across wide pallet surfaces, preventing flow length imbalance.

Hot runners maintain melt temperature and eliminate cold slugs, ensuring more uniform filling compared with traditional cold runners.

Moldflow or similar software allows designers to predict air traps, weld lines, and pressure drops before mold fabrication.

Adjusting gate width, thickness, or angle can significantly improve flow stability and reduce defects.

The gating and runner systems play an essential role in determining overall product quality. When thoughtfully designed, they greatly enhance filling uniformity, reduce structural defects, and improve the long-term durability of pallets. By combining optimized gate placement, balanced runners, and flow simulation analysis, manufacturers can achieve consistent, high-quality molding performance in modern pallet production.