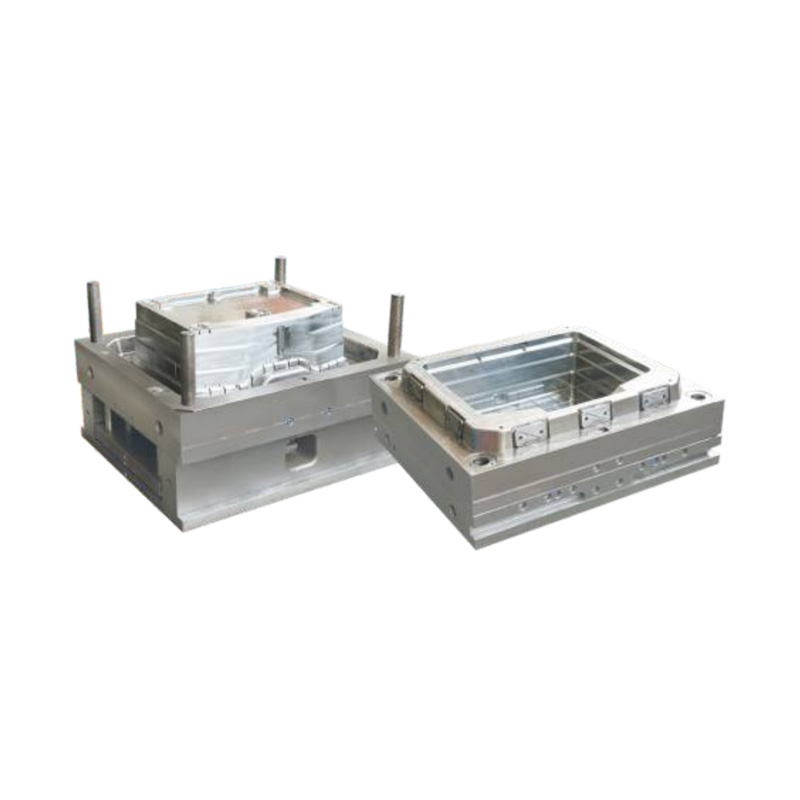

Drum Shaft and Pulsator Plastic Mold for Washing Machine

The plastic mold of the drum shaft impeller of the washing machine is ...

The design of a Plastic Commodity Mold significantly affects production efficiency and product quality. One of the important considerations is whether the mold utilizes a single cavity or multiple cavities. Multi-cavity molds allow several parts to be produced simultaneously, increasing output, but they also introduce challenges related to uniform filling and consistency.

• Multi-cavity molds allow manufacturers to produce multiple parts per injection cycle.

• This reduces cycle time per part and lowers labor and operational costs.

• Producing multiple parts simultaneously requires careful management of flow balance.

• Uneven filling can cause variations in part quality, including warpage, sink marks, or incomplete filling.

• Proper runner and gate design ensures that molten plastic reaches each cavity evenly.

• Unbalanced flow can cause some cavities to fill faster, resulting in inconsistent product weight and dimensional accuracy.

• Symmetrical gate placement is crucial to maintain uniform flow.

• Gates must be optimized based on part geometry, cavity distance, and material flow characteristics.

• Multi-cavity molds may have hotspots if cooling channels are not properly designed.

• Uneven temperature can affect flow viscosity, causing incomplete filling in some cavities.

• Uniform filling ensures that all parts from the mold have the same dimensions.

• Variations in cavity pressure or temperature may result in differences between parts, which is unacceptable for precision commodities.

• Multi-cavity molds require uniform injection and cooling to avoid surface defects such as flow lines or sink marks.

• Proper mold polishing and coating help maintain surface quality across all cavities.

• Uneven filling can create weak points in plastic parts, especially in thin-walled sections.

• Balanced flow and pressure are necessary to ensure consistent material density and mechanical performance.

• Full-round or trapezoidal runners help maintain pressure and temperature consistency across cavities.

• Balancing the runner lengths prevents pressure drops in distant cavities.

• Hot runners reduce waste and maintain uniform melt temperature.

• They are particularly effective in multi-cavity molds to improve filling consistency.

• Software such as Moldflow can simulate melt flow, cavity filling, and temperature distribution.

• Engineers can adjust gate size, placement, and runner design before mold fabrication to avoid defects.

• Cooling channels should be evenly distributed to maintain uniform temperature across all cavities.

• This prevents warpage and helps reduce cycle time while ensuring consistent part quality.

• Multi-cavity molds require frequent checks for wear, clogging, or misalignment in runner systems.

• Ensuring uniform flow paths preserves quality across production batches.

• Cleaning and lubricating ejector systems and gates prevents blockages and uneven filling.

• Scheduled maintenance improves longevity and reduces downtime.

Multi-cavity mold design plays a crucial role in determining the efficiency and quality of a Plastic Commodity Mold. Proper attention to gate placement, runner balance, temperature management, and cooling ensures uniform filling and consistent part quality across all cavities. By combining careful engineering, simulation tools, and preventive maintenance, manufacturers can improve productivity while maintaining high-quality standards for plastic commodity products. Multi-cavity molds, when well-designed, offer both efficiency and reliability for large-scale production operations.