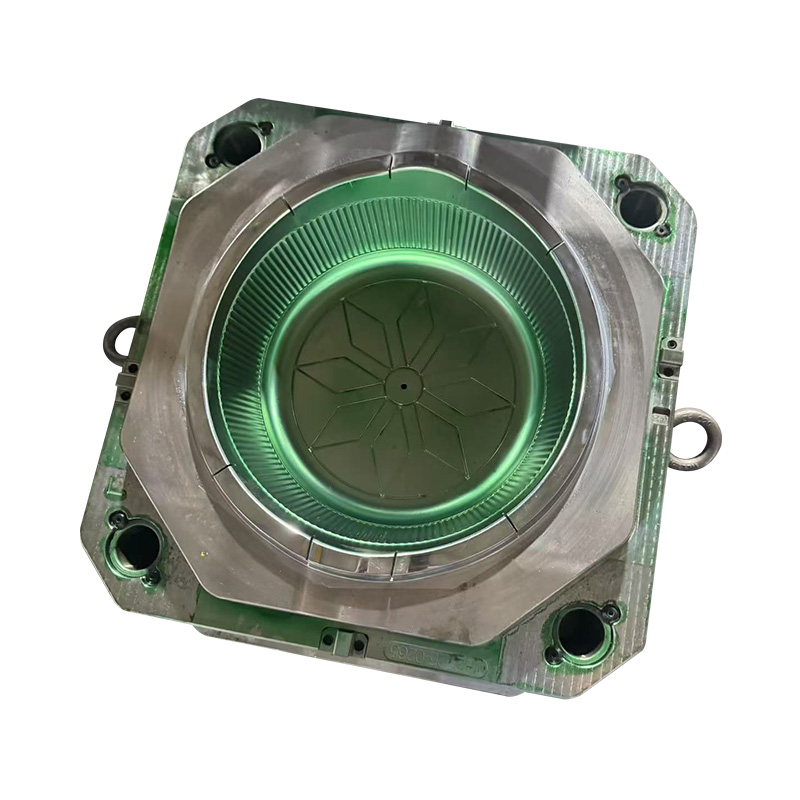

Embedded Ceiling Exhaust Fan Integration Mold

Embedded integrated ceiling exhaust fan mold is a high-precision injec...

At the early stage of mold development, defining how the basket will be used is essential. A Plastic Basket Mold must reflect real application conditions, such as loading, stacking, and handling frequency.

The expected load weight, whether static or dynamic, directly affects structural decisions. Baskets used for industrial transport require stronger ribs and thicker bottoms than those for household storage.

Many plastic baskets are designed to stack or nest for space efficiency. Mold designers must consider stop features, step structures, and consistent draft angles to ensure smooth stacking without deformation.

Handles, grip holes, and ventilation openings influence user experience. These elements must be structurally reinforced while remaining easy to mold and demold.

Wall thickness uniformity is one of the critical structural considerations in basket mold design. Poor control often causes warpage, sink marks, or weak areas.

Maintaining consistent wall thickness ensures even material flow and cooling. Sudden thickness changes should be avoided or transitioned gradually to reduce internal stress.

Ribs improve stiffness without increasing material usage. Their height, thickness, and spacing must be carefully calculated to prevent sink marks while still enhancing strength.

The bottom and corners usually bear the high loads. Additional ribs or thicker sections in these areas help distribute stress and extend product life.

Smooth and damage-free demolding is essential for efficient mass production. Structural features must support easy ejection without compromising basket performance.

Adequate draft angles on vertical walls, ribs, and holes reduce friction during ejection. Textured surfaces require larger draft angles than smooth ones.

Undercuts increase mold complexity and cost. If unavoidable, they should be reduced or designed with sliders or lifters that maintain mold reliability.

The structure should allow the ejection force to be evenly distributed across the product. Flat and reinforced areas are preferred contact points for ejector pins.

Many plastic baskets feature perforated walls for ventilation or weight reduction. These design elements must balance appearance, strength, and moldability.

Rounded or oval openings reduce stress concentration compared to sharp-edged shapes. Symmetrical layouts help maintain structural balance during loading.

Sufficient steel thickness must remain between perforations to maintain mold strength and prevent premature wear or breakage.

Textures and patterns enhance aesthetics and grip but affect flow and release. Structural design must account for texture depth and its influence on demolding.

Structural features should never be designed in isolation. They must align with mold flow, cooling, and long-term durability requirements.

Smooth transitions between ribs, walls, and corners promote stable melt flow and reduce weld lines or short shots.

Thick structural areas require enhanced cooling. Designers must ensure that rib and corner structures allow space for effective cooling channels.

Repeated molding cycles place stress on thin steel sections. Structural designs should protect vulnerable mold areas to extend service life and reduce maintenance costs.

An effective Plastic Basket Mold design achieves a balance between product performance and production efficiency.

Optimized structures reduce material consumption without sacrificing strength, helping control production costs.

Overly complex structures increase machining difficulty and mold cost. Simplified yet functional designs are often more reliable in long-term production.

Structural consistency ensures stable quality across large production volumes, reducing rejects and improving overall manufacturing efficiency.

By carefully addressing these structural design points, manufacturers can produce plastic baskets that are strong, durable, visually appealing, and suitable for high-efficiency injection molding operations.