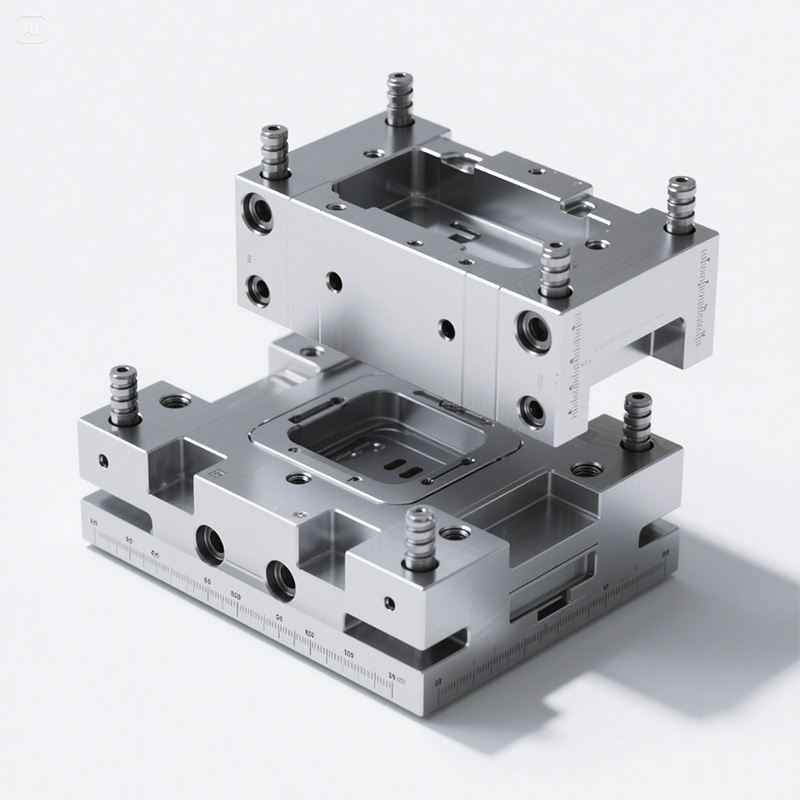

Round Exhaust Ventilation Fan Plastic Mold

The circular ventilation and exhaust fan plastic mold is a high-precis...

Precision plays a decisive role in determining not only the accuracy of the final product but also the efficiency of the entire production cycle. For industries ranging from automotive to consumer goods, the ability to create exact molds translates into consistent results and lower production costs. In today's globalized marketplace, businesses rely heavily on trustworthy injection mold suppliers and the expertise of every experienced injection mould manufacturer.

The most immediate benefit of accuracy in injection mold construction is product quality. Plastic parts need to meet exact dimensions, particularly when they are components in larger assemblies such as vehicles, medical devices, or electronic equipment. Even the smallest deviation can cause malfunction or safety issues. For this reason, customers often seek injection mold suppliers who can guarantee tolerance levels down to microns. A skilled injection mould manufacturer ensures that each mold cavity aligns perfectly, producing parts that fit seamlessly and perform reliably.

Another critical aspect of precision in injection mold construction is its impact on production efficiency. Accurate molds minimize material waste and reduce cycle times, resulting in significant cost savings during high-volume manufacturing. Reliable injection mold suppliers provide molds that can withstand millions of production cycles without losing accuracy. When businesses partner with a professional injection mould manufacturer, they benefit from stable, repeatable production runs that keep assembly lines running smoothly. This efficiency is vital in industries such as packaging, where speed and consistency are paramount.

Precision today is not only a matter of craftsmanship but also of advanced technology. Modern injection mold construction integrates CAD/CAM systems, high-speed CNC machining, and EDM (Electrical Discharge Machining) processes. These tools enable the creation of highly complex geometries that were once impossible. The most competitive injection mold suppliers invest heavily in technology to stay ahead. Similarly, a top-tier injection mould manufacturer leverages advanced software and hardware integration to deliver innovative solutions for clients seeking unique designs or specialized applications.

Durability is closely linked to precision. When injection mold construction is carried out with meticulous attention to detail, the resulting mold has a longer service life. Poorly designed or imprecise molds may wear out quickly, causing frequent downtime and costly repairs. Trustworthy injection mold suppliers ensure that the materials used, whether tool steel or hardened alloys, are properly processed and treated. A professional injection mould manufacturer also applies quality control procedures, such as hardness testing and mold flow analysis, to ensure the mold maintains its accuracy over years of operation.

In today's international trade environment, many companies work with injection mold suppliers overseas. Precision becomes even more important when molds are manufactured across borders. Businesses must have confidence that the injection mould manufacturer they select can meet stringent international standards and deliver products that require little or no reworking. With precise injection mold construction, communication between client and supplier is simplified, as specifications can be met consistently regardless of location. This reliability builds long-term partnerships and reduces supply chain risks.

Precision enables innovation. Complex product designs, intricate surface textures, and unique geometries all depend on accurate injection mold construction. For industries that demand differentiation—such as consumer electronics or medical devices—precision molds are essential. Many injection mold suppliers now offer customization services tailored to specific client needs. An innovative injection mould manufacturer can transform a concept into a fully functional mold that captures even the smallest design detail, helping brands bring new products to market faster.

The role of precision in modern injection mold construction cannot be overstated. From ensuring product quality and efficiency to enhancing durability and enabling innovation, precision directly influences the success of manufacturing operations. The partnership between reliable injection mold suppliers and skilled injection mould manufacturer professionals is the backbone of consistent, cost-effective, and innovative plastic production. As industries continue to evolve, the demand for precision will only grow, reinforcing its central role in shaping the future of manufacturing.