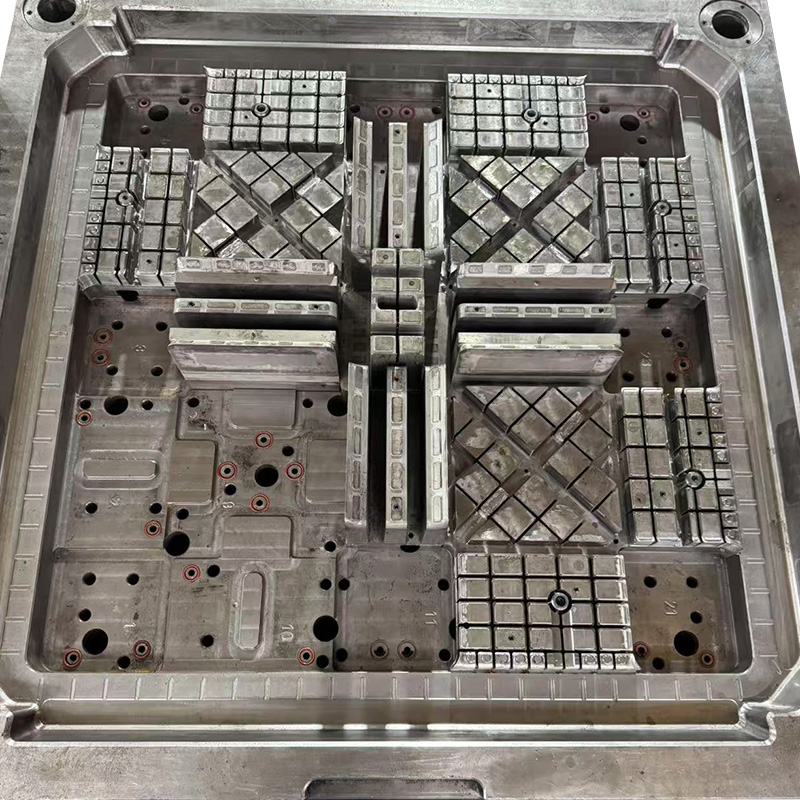

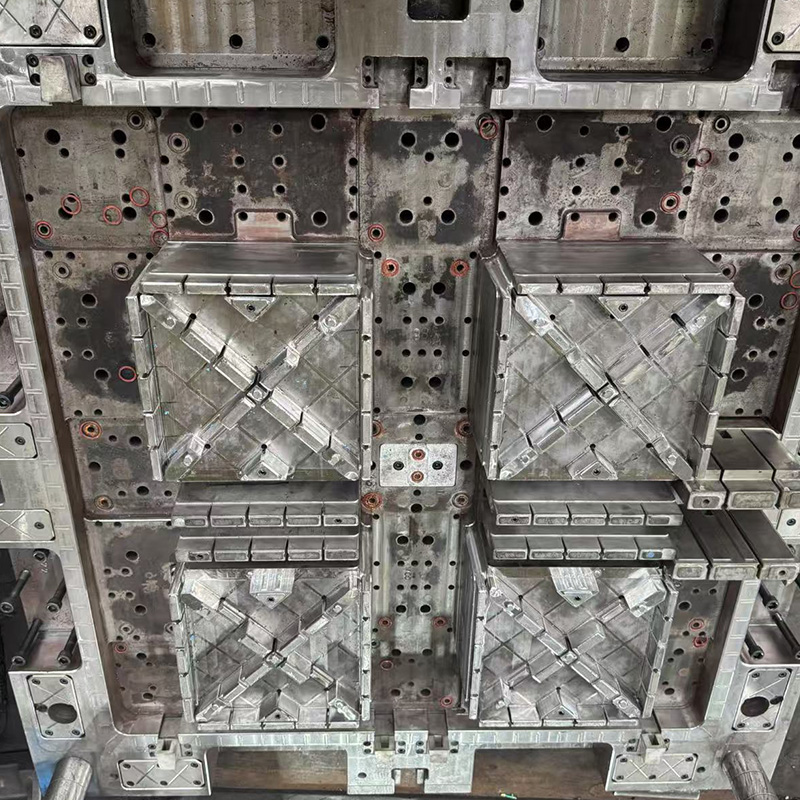

Twin-Tub Semi-Automatic Washing Machine Mold

The double-barrel semi-automatic washing machine mold is a high-precis...

A growing chorus of logistics managers, sustainability officers, and environmental advocates are turning their attention to the substantial ecological advantages of injection molded plastic pallets. This transition is not merely a matter of operational efficiency; it is a conscious step towards a more sustainable and circular economy.

The most immediate environmental benefit of molded plastic pallets is their exceptional durability. Unlike their wooden counterparts, which are prone to splintering, cracking, and absorbing moisture, plastic pallets are built to last. The injection molded pallets process creates a single, monolithic piece of high-density polyethylene or polypropylene, resulting in a structure that can withstand hundreds of trips through supply chains. A single, long-lasting injection molded plastic pallet can replace dozens of single-use or repaired wooden pallets throughout its lifespan. This dramatic reduction in replacement frequency directly translates to less raw material extraction, lower energy consumption for manufacturing replacements, and a significant decrease in waste destined for landfills.

In industries where hygiene is paramount, such as pharmaceuticals, food and beverage, and electronics, the non-porous surface of molded plastic pallets offers a critical advantage. Wooden pallets can harbor bacteria, pests, and mold, leading to product contamination and massive waste. They often require fumigation with harmful chemicals like methyl bromide, a known ozone-depleting substance. Injection molded pallets, by contrast, can be easily and thoroughly cleaned with steam or disinfectants without risking structural damage. This eliminates the need for toxic chemical treatments and prevents the spoilage of valuable products, thereby conserving the resources and energy already invested in producing those goods.

The weight of a pallet might seem insignificant, but when multiplied across thousands of shipments, it has a substantial impact on fuel consumption and greenhouse gas emissions. While exceptionally strong, injection molded plastic pallets are consistently lighter than their hardwood equivalents. This weight reduction means that trucks, ships, and planes can carry more payload and less tare weight (the weight of the packaging itself). For a large fleet, this marginal gain in efficiency compounds into massive savings in fuel and a corresponding reduction in carbon emissions. The consistent design and weight of injection molded plastic pallets also allow for more optimized loading and stacking, further enhancing transportation efficiency.

Perhaps the most compelling environmental argument for plastic pallets lies in their end-of-life potential. At the end of their long service life, which can span over a decade, molded plastic pallets are fully recyclable. They can be ground down and reintroduced as raw material for manufacturing new products, including new pallets. This creates a closed-loop system that stands in stark contrast to the typical fate of damaged wooden pallets, which are often downcycled into mulch, burned, or landfilled. The high-quality resin from injection molded pallets retains its value and properties, making it a desirable feedstock. This commitment to recyclability ensures that the material remains in use for as long as possible, embodying the principle of a circular economy and reducing the demand for virgin petroleum-based plastics.

The production of wooden pallets contributes to deforestation and requires a continuous input of fresh timber. The creation of injection molded plastic pallets, however, is a story of resource efficiency. A significant portion of molded plastic pallets on the market today are manufactured using a high percentage of post-consumer or post-industrial recycled plastic. This process gives a second life to items like milk jugs and detergent bottles, diverting waste from oceans and landfills. Furthermore, the manufacturing process for injection molded plastic pallets is highly precise, generating very little material scrap compared to the cutting and milling of wood. Any scrap that is produced during the injection molded pallets manufacturing cycle can be immediately reground and reused, minimizing waste from the very beginning.

The standardized dimensions and consistent quality of injection molded plastic pallets lead to fewer operational failures in automated warehouses and distribution centers. A broken stringer or a protruding nail on a wooden pallet can jam sophisticated conveyor systems, leading to downtime, product damage, and waste. The robust and uniform nature of injection molded plastic pallets ensures smooth operation, reducing these instances of waste and inefficiency. This reliability prevents costly disruptions and contributes to a leaner, more waste-averse supply chain.