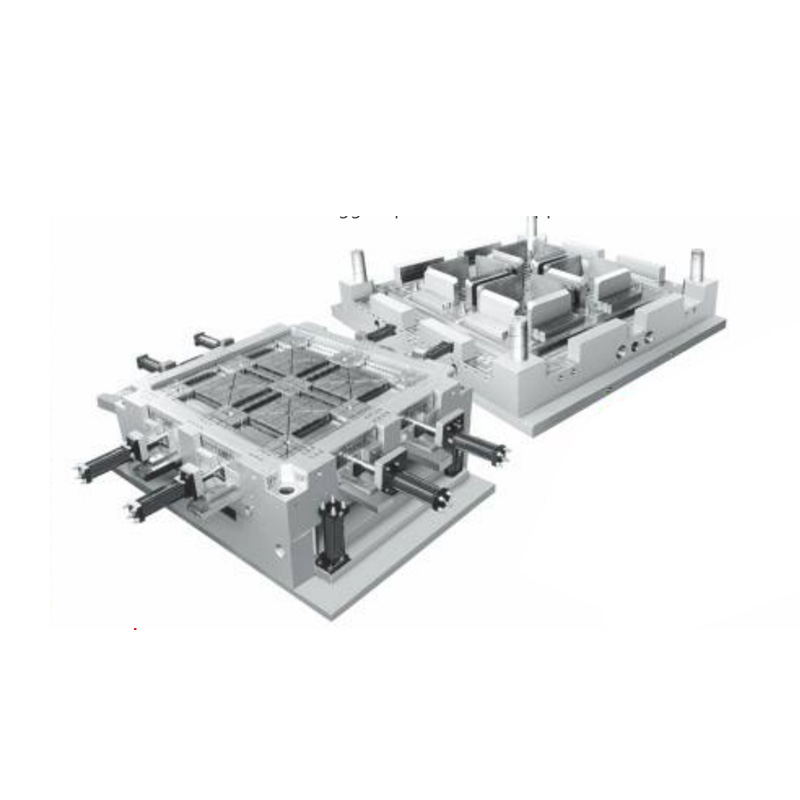

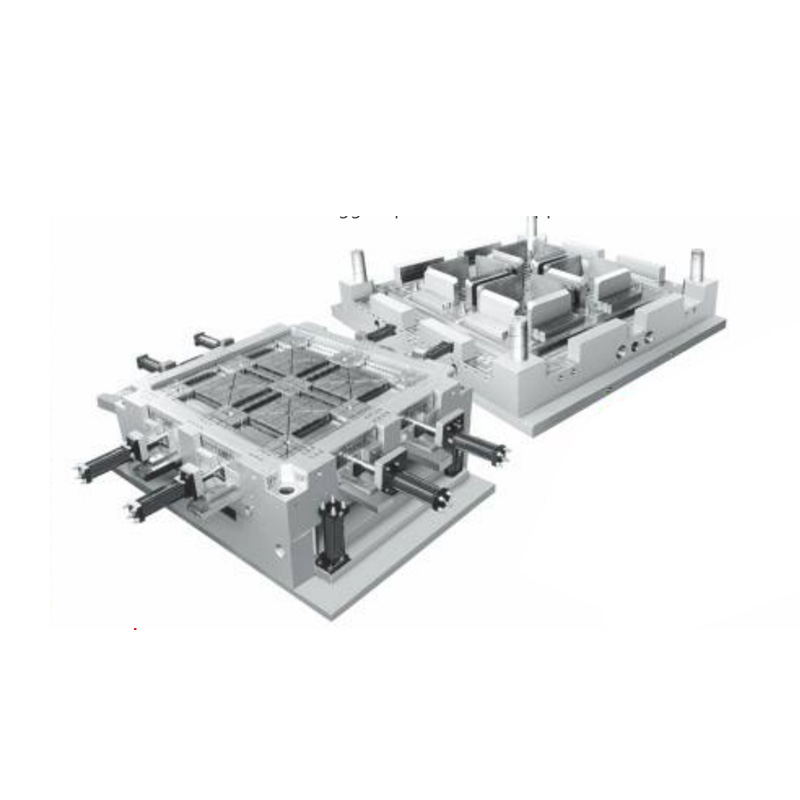

Plastic Pallet Mold is essential in manufacturing high-quality pallets used widely in logistics, warehousing, and transportation industries. One of the pressing challenges during production is the formation of porosity and other defects. Such issues can compromise structural integrity, reduce product lifespan, and affect aesthetic quality. Understanding the underlying causes and implementing effective preventive measures is critical for achieving consistent and reliable production outcomes.

Primary Causes of Porosity and Defects

- Entrapped Air: During injection molding, air may become trapped within mold cavities, resulting in bubbles or voids inside the pallet.

- Uneven Material Flow: Inconsistent flow of molten plastic can create cold spots, incomplete filling, or surface irregularities.

- Moisture in Resin: Plastic pellets containing residual moisture can vaporize when heated, forming bubbles and causing defects.

- Improper Mold Temperature: Uneven heating or cooling can cause warping, shrinkage, and internal stress, increasing defect likelihood.

- Excessive Injection Pressure: High pressure may cause flash, burrs, or micro-cracks, negatively affecting both structural and surface quality.

Design Considerations for Defect Reduction

- Optimized Venting System: Properly placed vents allow trapped air to escape, reducing internal void formation.

- Strategic Gate and Runner Placement: Correct positioning ensures smooth and uniform material flow, preventing cold spots and incomplete filling.

- Polished Mold Surfaces: Smooth or coated cavity surfaces enhance material flow, reduce adhesion, and prevent localized defects.

- Uniform Cooling Channels: Even cooling prevents warping, stress concentrations, and thermal-related imperfections.

- Reinforced Critical Areas: Corners, edges, and other high-stress regions can be reinforced to resist deformation or void formation.

Material and Process Control Strategies

- Pre-Drying Raw Material: Eliminating moisture from plastic pellets prevents vapor-induced bubbles and internal porosity.

- High-Quality Resin Selection: Consistent and pure resin reduces impurities and variability that contribute to defects.

- Controlled Injection Parameters: Optimizing temperature, pressure, and injection speed ensures filling without overstressing the mold.

- Cycle Time Optimization: Adequate cooling and solidification time reduce surface defects, shrinkage, and internal voids.

Inspection and Quality Assurance Measures

- Visual Surface Checks: Regular inspection identifies porosity, warping, and cracks before pallets leave production.

- Non-Destructive Testing: Techniques such as ultrasonic or X-ray inspection detect internal voids without damaging the pallet.

- Process Monitoring: Continuous tracking of injection pressure, temperature, and flow ensures consistent operations and detects anomalies early.

- Feedback Loops for Adjustment: Insights from inspections allow real-time adjustments, maintaining product quality throughout production runs.

Advantages of Minimizing Porosity and Defects

- Enhanced Structural Strength: Reducing voids ensures pallets can support heavy loads and endure repeated use.

- Improved Aesthetic Quality: Smooth, defect-free surfaces meet visual standards and customer expectations.

- Reduced Material Waste: Fewer defective pallets lower production costs and decrease downtime.

- Increased Product Reliability: Consistent, high-quality pallets provide safer handling and longer service life.

- Operational Efficiency: Minimizing defects reduces rework, streamlines production, and enhances overall manufacturing efficiency.

Achieving High-Quality Production with Plastic Pallet Mold

Porosity and defects remain key challenges in Plastic Pallet Mold production, affecting both durability and appearance. Addressing these issues requires a combination of precise mold design, high-quality raw materials, and rigorous process control. Optimized venting, gate placement, polished surfaces, uniform cooling, and material pre-drying all contribute to reducing defects. Coupled with inspection, monitoring, and timely adjustments, these strategies ensure that manufacturers can produce durable, high-quality pallets with waste and efficiency. By understanding and mitigating the causes of porosity and defects, production processes can meet both operational standards and customer expectations consistently.