Single-Tub Spin Dryer Washing Machine Mold

Single-barrel spin-drying washing machine molds are mainly used to pro...

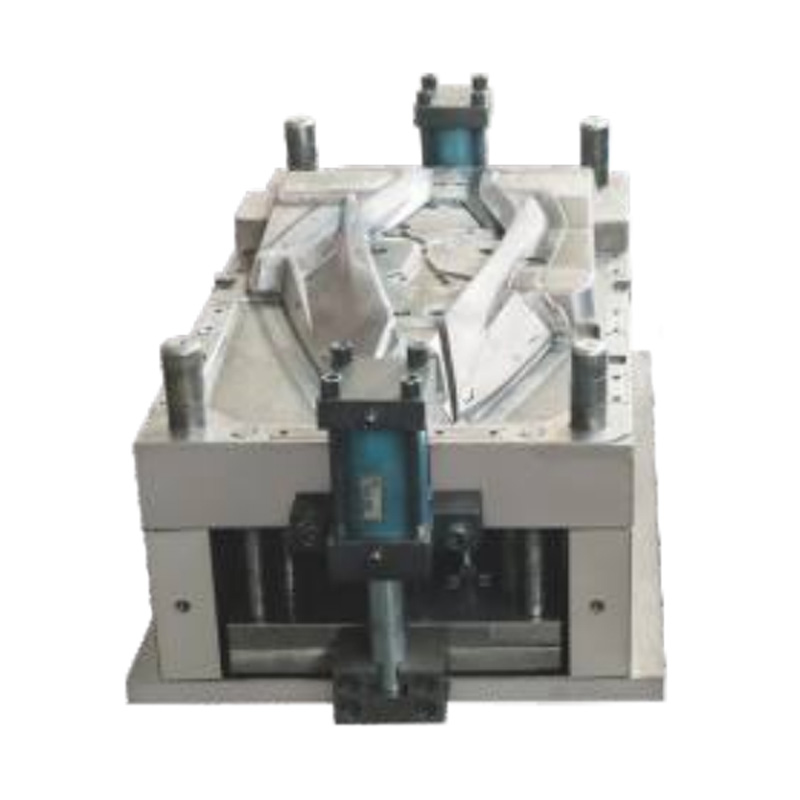

When it comes to modern vehicle manufacturing, the role of a Plastic Automobile Parts Mold extends far beyond shaping raw material into functional forms. Dimensional accuracy is one of the critical requirements in automotive components, as even minor deviations can cause improper assembly, reduced performance, or safety concerns. Whether producing dashboards, bumpers, or intricate under-the-hood elements, ensuring exact dimensions is fundamental to the reliability and efficiency of the entire vehicle system. Achieving this level of precision requires the integration of advanced engineering principles, strict quality control, and innovative mold-making technologies.

Precision begins with design. The geometry of the mold must be carefully developed using computer-aided design (CAD) and computer-aided engineering (CAE) tools. By simulating the injection process in advance, engineers can predict shrinkage, warpage, and dimensional deviations before production starts. Optimizing gate placement, runner balance, and cavity configuration ensures uniform material flow, which directly contributes to dimensional consistency. The use of finite element analysis (FEA) further enhances the ability to model stress distribution and thermal effects, preventing irregular shrinkage that could compromise accuracy.

The type of plastic resin chosen for automotive parts significantly influences dimensional precision. Different polymers exhibit varying shrinkage rates and thermal expansion properties, which must be factored into mold design. Reinforced plastics, such as those containing glass fibers, help reduce deformation and improve stability under mechanical stress. Material testing during the design stage provides essential data on flow characteristics, cooling behavior, and dimensional tolerance, ensuring that the selected resin supports both the structural and precision requirements of automotive applications.

Even the designs rely on the quality of mold fabrication. High-precision machining techniques such as CNC milling, EDM (electrical discharge machining), and grinding are used to achieve exact cavity dimensions and surface finishes. Tolerances in mold components are held to extremely tight standards to prevent dimensional drift during repeated production cycles. The use of hardened steels or wear-resistant alloys ensures that the mold retains its accuracy even under high-volume manufacturing conditions. Precision assembly of mold inserts, cooling channels, and ejector systems also plays a key role in maintaining uniformity throughout the production process.

Maintaining dimensional accuracy is not solely dependent on design and materials but also on process stability. Injection pressure, holding pressure, melt temperature, and cooling rate must all be carefully monitored and controlled. Automated monitoring systems with real-time data feedback allow operators to adjust parameters quickly to prevent deviations. After molding, components undergo strict quality inspections, including coordinate measuring machine (CMM) analysis and optical scanning, to confirm compliance with dimensional specifications. Consistent feedback loops between production and design help refine both mold performance and process reliability.

Ensuring precision in molded automotive parts is an ongoing process that evolves with technological advancement. The use of digital twin simulations, advanced polymer blends, and intelligent mold temperature regulation systems represents the next step in precision engineering. By combining these innovations with rigorous quality standards, manufacturers can continue to deliver components that meet the increasingly demanding requirements of modern automotive design. Ultimately, the guarantee of dimensional accuracy ensures not only proper assembly but also the long-term performance and safety of vehicles worldwide.