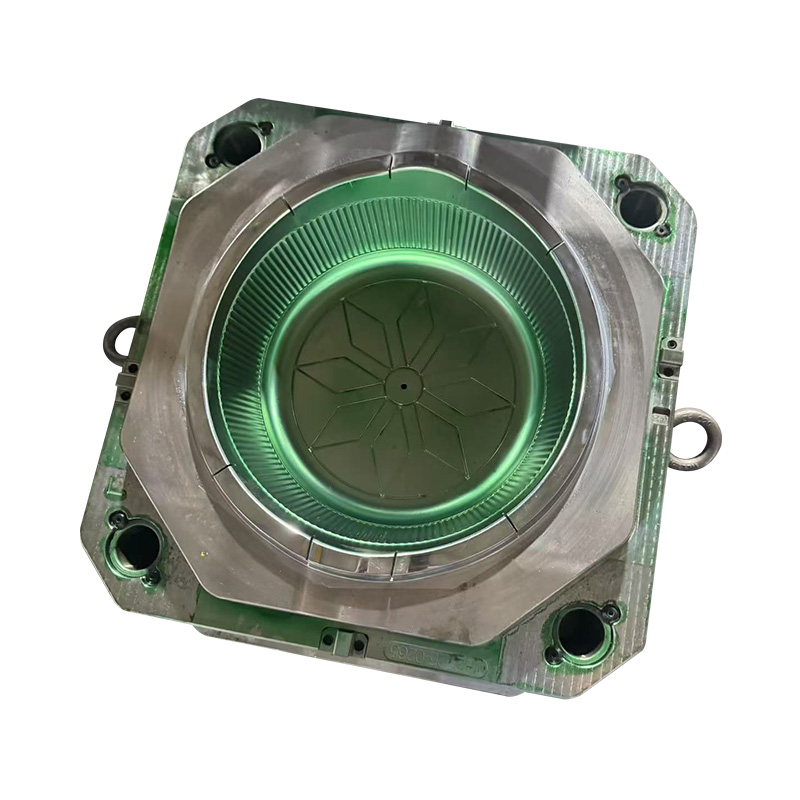

Stackable Large-Capacity Outdoor Trash Bin Mold with Optional Lid

The stackable large-capacity outdoor trash can mold is specially desig...

Clamping force is a critical parameter in the injection molding process. It ensures the mold remains closed under the pressure of molten plastic, preventing flash and maintaining product quality. For a high-quality Plastic Basket Mold, choosing the right clamping force is essential for efficient production.

Clamping force is the amount of pressure applied by the injection molding machine to keep the mold halves tightly closed during the injection process. It is usually measured in tons and must match the mold size, material, and injection pressure.

Insufficient clamping force can cause mold flash, dimensional inaccuracies, and warping. Excessive clamping force, however, increases wear on mold components and can cause unnecessary energy consumption. Selecting an appropriate force ensures uniform wall thickness and reduces defects.

Several factors must be considered when determining the suitable clamping force for a Plastic Basket Mold.

Larger molds or molds with extensive surface areas require a higher clamping force to counteract the injection pressure. Small molds need proportionally lower force. A general formula is to calculate the projected area of the part and multiply it by the injection pressure.

Different plastics have varying flow characteristics. High-viscosity materials such as ABS or PP require higher clamping force to prevent flash, while low-viscosity materials like PE may need less force. Material selection directly impacts the required clamping pressure.

Thicker sections generate more internal pressure during injection, necessitating a higher clamping force. Complex geometries with deep ribs or hollow sections may also require increased force to maintain mold integrity.

High injection pressure increases the tendency of the molten plastic to push mold halves apart. Therefore, the clamping force must be sufficient to counteract this pressure and prevent leakage.

Proper calculation ensures efficient operation and prevents mold damage.

Calculate the total projected area of the part in contact with the mold. Multiply this area by the injection pressure of the material to obtain the required clamping force in tons.

It is advisable to add a 10–20% safety margin to accommodate fluctuations in injection pressure and variations in material behavior. This ensures consistent product quality without overloading the mold.

Verify that the selected injection molding machine can provide the calculated clamping force. Using a machine with insufficient clamping capability may result in flash and part deformation.

Proper operation and maintenance help maintain suitable clamping performance and extend mold life.

Check mold alignment, guide pins, and clamping mechanisms regularly. Worn components can reduce effective clamping force, causing defects.

Start with a lower clamping force during initial trials and gradually increase it while monitoring part quality. This prevents excessive stress on the mold and reduces energy consumption.

Design features like rounded corners, uniform wall thickness, and balanced ribs can reduce the required clamping force while maintaining part strength.

Selecting the appropriate clamping force for a Plastic Basket Mold requires careful consideration of mold size, material type, wall thickness, and injection pressure. Accurate calculation, combined with machine capability and proper setup, ensures high-quality molded parts, reduces wear on the mold, and improves production efficiency. Following practices for maintenance and gradual adjustment helps maintain consistent performance and extends the lifespan of both the mold and the injection molding machine.