Stackable Mesh Plastic Pallet Injection Mold

The stackable grid plastic pallet injection mold is specially used to ...

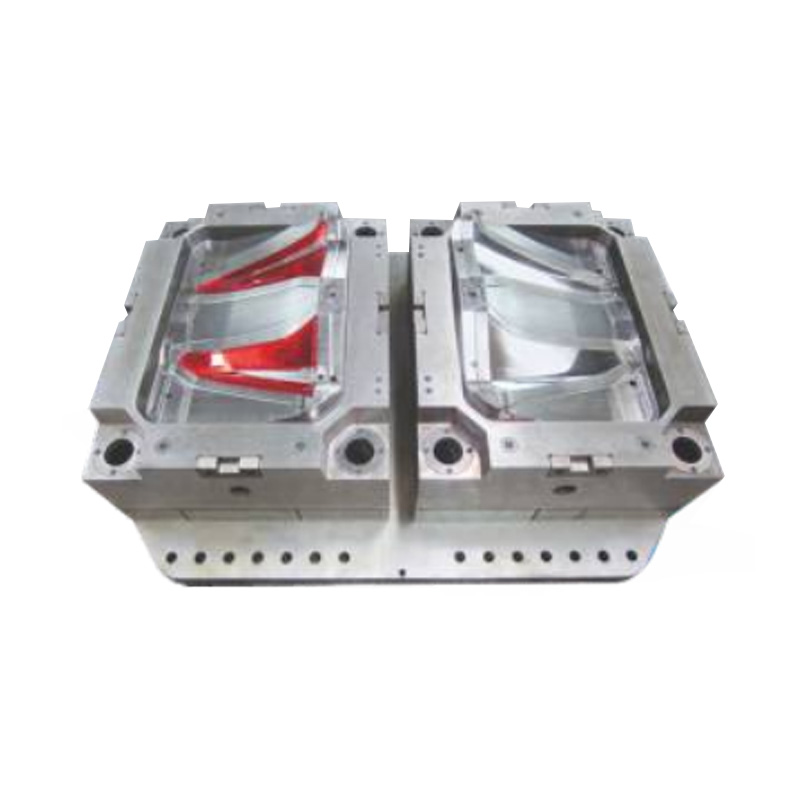

Modern automotive design increasingly relies on plastic parts with intricate shapes, thin walls, and integrated functions. A Plastic Automobile Parts Mold must accommodate these complex geometries while ensuring dimensional accuracy and high production efficiency.

Automotive interior and exterior components often feature curved surfaces and aesthetic contours. These freeform shapes complicate cavity machining and require precise CNC and EDM processes to achieve accurate replication.

Many plastic automobile parts integrate clips, snap-fits, ribs, and mounting features into a single component. This functional density increases the likelihood of undercuts and complex parting lines.

Complex geometries must still meet tight tolerances to ensure proper assembly with metal or electronic components. Mold design must balance complexity with dimensional stability.

Handling complex shapes and undercuts begins at the design stage, long before mold manufacturing starts.

Advanced CAD modeling combined with flow simulation helps engineers predict filling behavior, weld lines, and air traps in complex geometries. Early analysis reduces costly design revisions.

Choosing a suitable parting line simplifies mold structure and reduces the number of side actions required. Well-planned parting lines also improve surface appearance and sealing accuracy.

Minor geometry adjustments, such as adding fillets or modifying angles, can significantly reduce undercuts without affecting part function. This improves mold reliability and lowers manufacturing costs.

Undercuts are common in automotive plastic parts due to functional requirements. Specialized mold mechanisms are used to release these features during demolding.

Sliders are widely used to form lateral undercuts such as holes, clips, or slots. They move perpendicular to the mold opening direction and retract before ejection.

Lifters combine vertical and angled motion, making them suitable for internal undercuts that cannot be accessed by sliders. Proper angle design ensures smooth movement and long service life.

For large or heavily loaded side cores, hydraulic cylinders provide stable and controlled movement. Mechanical cam systems are often preferred for simpler structures due to lower maintenance requirements.

Complex geometries demand advanced manufacturing technologies to maintain accuracy and surface quality.

Five-axis CNC machining allows precise cutting of complex surfaces and deep cavities, reducing electrode usage and improving overall accuracy.

EDM is essential for sharp corners, deep ribs, and intricate details that are difficult to machine conventionally. It plays a key role in automotive mold production.

Accurate alignment of sliders, lifters, and cavities ensures smooth operation and prevents premature wear. High-precision assembly is critical for molds with multiple moving components.

Complex mold structures must perform reliably over long production cycles without frequent maintenance.

High-quality mold steels with good toughness and wear resistance are essential for side cores and moving parts subjected to repeated stress.

Proper lubrication channels and wear plates help reduce friction between moving components, extending mold life and maintaining precision.

Complex geometries often create uneven cooling. Targeted cooling around sliders and thick sections prevents warpage and ensures consistent part quality.

Successfully handling complex geometry and undercuts requires a balance between engineering ambition and practical manufacturing.

Each additional slider or lifter increases mold cost and maintenance. Designers must evaluate whether the functional benefit justifies the complexity.

2. Collaboration Between Designers and Toolmakers

Close communication between product designers and mold engineers helps identify potential issues early and develop efficient solutions.

A well-designed Plastic Automobile Parts Mold not only meets initial design requirements but also supports stable, high-volume production with downtime.

By combining thoughtful design optimization, advanced mechanical solutions, and precise manufacturing techniques, automotive mold makers can effectively manage complex geometries and undercut structures while delivering reliable and high-quality plastic components.