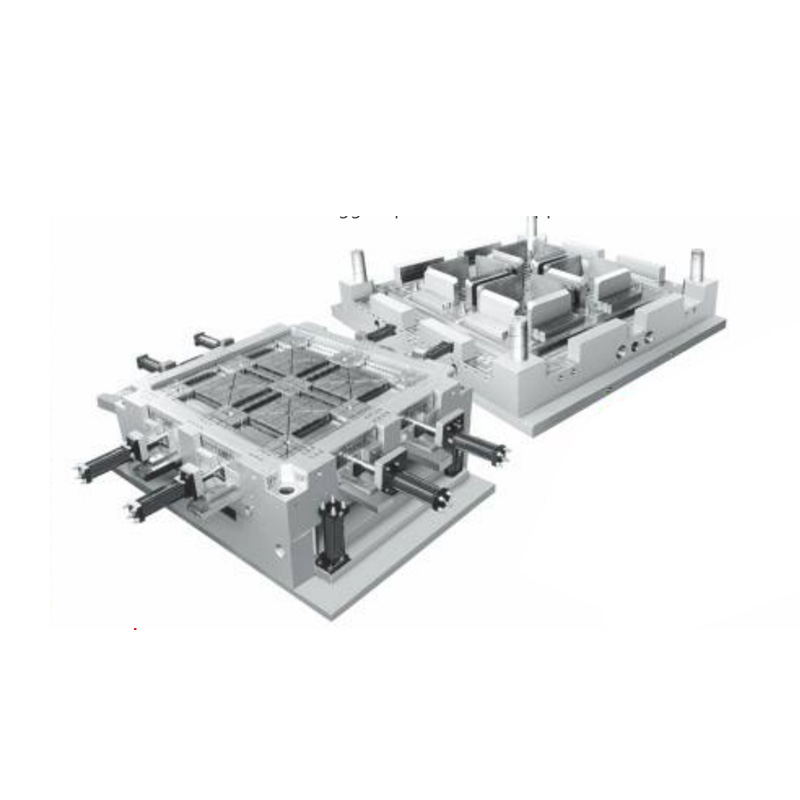

Household Appliance Air Cooler Mold

From the perspective of household appliance mold manufacturing, househ...

In large-scale manufacturing, achieving consistent dimensions in plastic pallets is essential for ensuring load-bearing capacity, stackability, and compatibility with automated handling systems. A Plastic Pallet Mold must be precisely engineered and managed to decrease variation across production batches. Deviations in dimensions can result in assembly issues, uneven wear, and compromised structural performance. Maintaining uniformity requires attention to mold design, process control, material quality, and ongoing monitoring to ensure that every pallet produced meets strict specifications.

1. Precision Fabrication

Utilizing high-grade steel and CNC machining ensures that mold cavities maintain strict tolerances.

Coordinate measuring machines (CMM) or laser scanning verify cavity geometry before production.

2. Gate and Runner System Optimization

Proper placement of gates and runners ensures a uniform flow of molten material into all mold sections.

Balanced flow reduces uneven filling, shrinkage, and stress concentration, which directly affect dimensional consistency.

3. Wall Thickness and Structural Reinforcement

Consistent wall thickness prevents differential cooling and reduces the risk of warping or internal stresses.

Reinforcing ribs should be designed to strengthen key areas without causing localized shrinkage.

1. Injection Pressure and Speed Control

Maintaining a stable injection pressure ensures that the molten polymer fully packs the cavity.

Controlled injection speed prevents turbulence and jetting, reducing defects that could alter dimensions.

2. Temperature Stability

Consistent mold temperature is critical for uniform cooling, preventing warping or shrinkage.

Material temperature must be monitored to maintain predictable flow and solidification behavior.

3. Cooling Time and Cycle Optimization

Adequate cooling time allows uniform solidification of the pallets, reducing internal stresses.

Automated cooling channels ensure even heat dissipation across the mold, reducing dimensional deviations.

1. Homogeneity of Raw Materials

Using high-quality plastic pellets with a consistent melt flow index and moisture content reduces shrinkage variation.

Homogeneous material prevents density differences that could affect dimensional stability.

2. Additives and Fiber Reinforcements

Glass fibers or mineral fillers must be uniformly mixed to prevent localized deformation.

Inconsistent dispersion can cause weak spots, warping, or uneven thickness in the finished pallet.

1. In-Process Inspection

Regular measurements using calipers, micrometers, or laser scanning identify deviations early in the production run.

Automated vision systems can continuously monitor dimensions for high-volume production, enabling immediate corrective action.

2. Feedback and Parameter Adjustments

Dimensional deviations can be corrected by adjusting injection pressure, cooling time, or gate balance.

Fine-tuning mold settings between production batches ensures long-term consistency.

1. Routine Cleaning and Polishing

Residue buildup or minor wear can affect cavity dimensions, so regular maintenance is essential.

Polishing ensures smooth cavity surfaces, preventing defects that may alter dimensions.

2. Component Alignment and Calibration

Periodic inspection of mold alignment and moving parts prevents cumulative deviations in the final product.

Replacing worn or misaligned components ensures consistent dimensional output across production cycles.

Maintaining dimensional consistency in mass production relies on a comprehensive approach combining precise Plastic Pallet Mold design, controlled processing conditions, high-quality material usage, and rigorous monitoring. Balanced runner systems, stable temperatures, proper cooling, and consistent material properties reduce the risk of variation. Continuous inspection and adaptive adjustments further enhance reliability, ensuring that every pallet meets exacting specifications. By integrating these strategies, manufacturers can produce durable, stackable, and dimensionally accurate pallets suitable for high-volume logistics and industrial applications, demonstrating the critical role of mold design and process management in achieving consistent production quality.