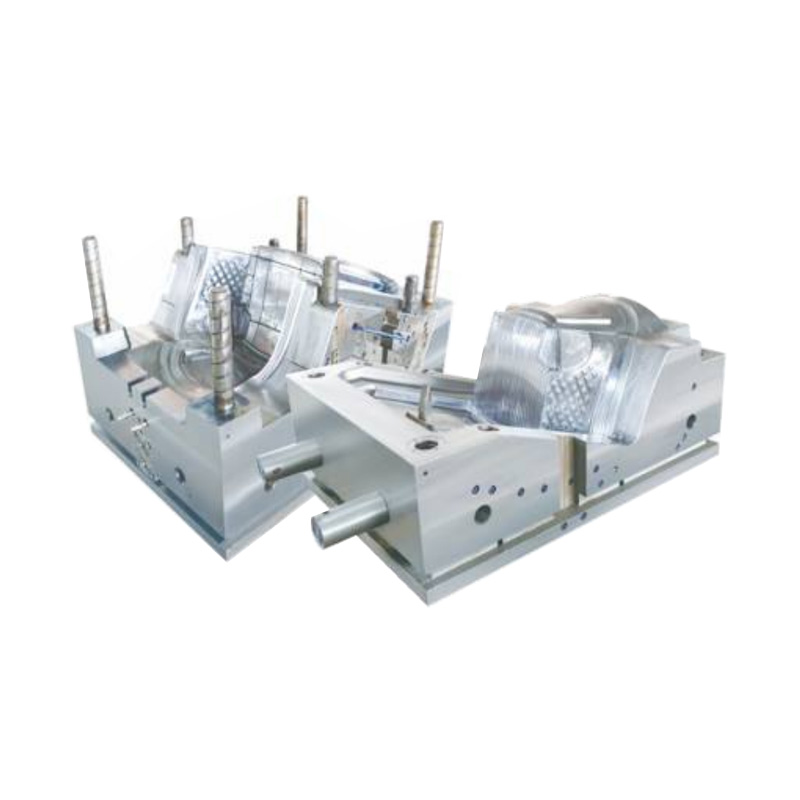

Industrial Air Cooler Plastic Mold

As an OEM factory specializing in the design and manufacture of air co...

In the manufacturing of plastic furniture, the internal design of the flow system plays a crucial role in determining the final product’s mechanical characteristics. Within a Plastic Chair Mold, the layout of the runner system directly dictates how molten polymer travels through the cavity and solidifies. This flow behavior affects the uniformity of the material, the bonding strength between regions, and ultimately the overall load-bearing performance of the chair. Engineers must balance efficiency and structure by designing runners that decrease flow resistance while ensuring even pressure and temperature distribution across the mold cavity.

1. Balanced Filling and Pressure Transmission

A well-designed runner system ensures that the molten material reaches all parts of the mold at nearly the same time. When flow is evenly balanced, internal stresses are reduced, and the plastic chair develops consistent density across its structure. If one side fills faster than another, residual stresses can occur, resulting in weak spots that reduce overall durability.

2. Influence of Runner Size and Geometry

Runner dimensions determine the velocity and volume of molten material entering each cavity section. Oversized runners can cause excessive pressure loss, while undersized runners may restrict flow, causing incomplete filling or localized thinning. Both conditions result in irregular strength distribution, making certain areas more prone to cracking or deformation under load.

1. Temperature Gradient Management

The molten polymer begins to cool the moment it leaves the nozzle. If the runner system does not maintain uniform thermal conditions, sections of the mold may solidify at different rates. This uneven cooling can cause warpage or varying levels of crystallinity within the material, both of which weaken structural uniformity.

2. Hot Runner vs. Cold Runner Performance

Hot runner systems help maintain material flow temperature consistency, which is beneficial for structural integrity. They reduce the formation of weld lines and air traps, ensuring that the plastic maintains continuous molecular bonding. In contrast, cold runners can create abrupt temperature drops that form internal stress points, especially in large molds used for chair production.

1. Controlling Fiber Alignment in Reinforced Plastics

For reinforced chairs made with glass fiber or mineral-filled polymers, the runner design affects how fibers align during flow. Directional flow patterns can cause fibers to orient along certain paths, enhancing strength in one direction but potentially weakening it in another. By optimizing gate locations and runner layout, designers can control fiber distribution for balanced multi-directional strength.

2. Reducing Weld and Knit Lines

Poor runner placement can cause multiple flow fronts that meet improperly, forming weld or knit lines. These zones often exhibit weak bonding, which significantly reduces structural strength. Correct runner geometry and gate angles can guide flow fronts to merge under higher temperature and pressure, improving molecular fusion and enhancing mechanical integrity.

1. Reducing Internal Stresses

Uneven pressure distribution during injection can result in residual stress once the product cools. A symmetrical runner network equalizes flow resistance, ensuring that each section of the mold experiences similar internal pressure. This approach prevents bending or warping after demolding.

2. Controlling Flow Rate for Structural Stability

If the flow rate is too fast, jetting may occur—causing turbulence and incomplete bonding between polymer layers. If too slow, premature cooling can hinder material fusion. The ideal runner design maintains steady velocity to optimize material cohesion, which directly translates to higher structural reliability.

The runner system design in a Plastic Chair Mold is far more than a channel for molten material—it is a key engineering component that determines how strength is distributed throughout the final product. From maintaining temperature balance and fiber orientation to controlling pressure and flow rate, each factor influences structural consistency. When optimized, the runner system enables the production of chairs that combine aesthetic appeal with good durability and performance. The synergy between flow design and mechanical engineering ensures that every molded chair maintains reliable strength across all load-bearing points, demonstrating the vital link between internal mold architecture and long-term product quality.