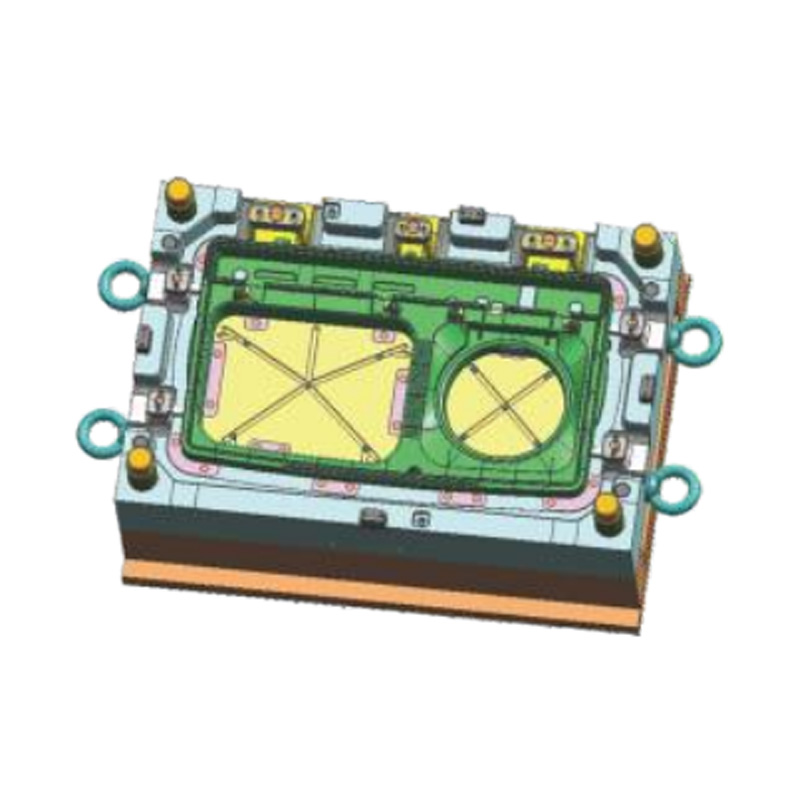

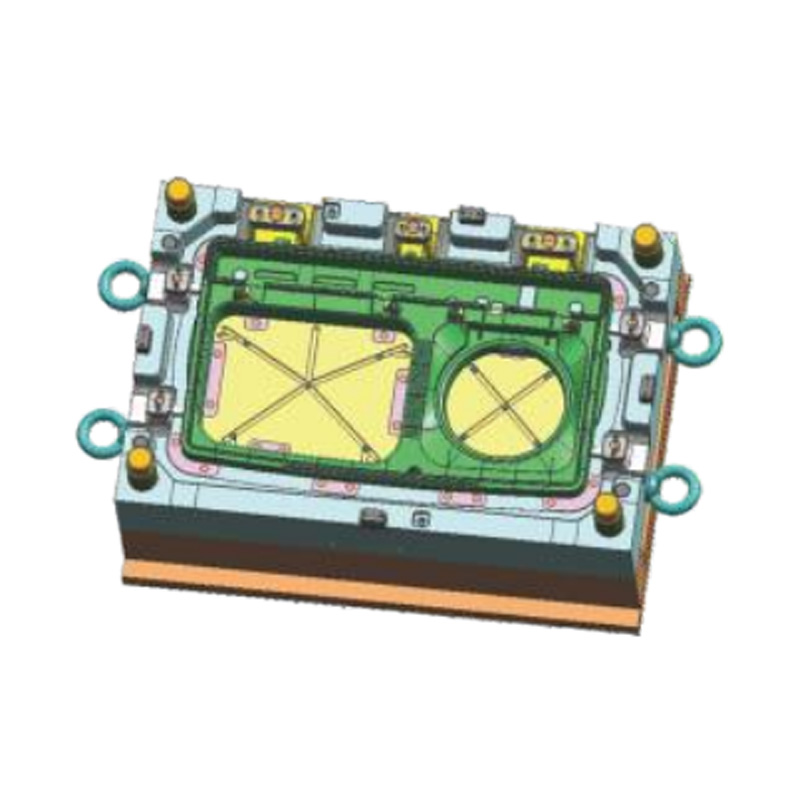

Plastic Chair Mold is a critical tool for manufacturing ergonomic and aesthetically pleasing chairs used in homes, offices, and public spaces. Producing complex chair designs often involves intricate geometries, varying wall thicknesses, and multiple cavities. One of the common challenges in such scenarios is ensuring proper runner and gate design to avoid flow shortages. Inadequate flow can cause incomplete filling, surface defects, and structural weaknesses, which compromise both the appearance and functionality of the final product. Understanding and mitigating these challenges is essential for efficient production.

Causes of Runner Shortages in Complex Molds

- Intricate Mold Geometry: Complex shapes with curves, recesses, or thin sections can create resistance to molten plastic flow, causing underfilled areas.

- Uneven Wall Thickness: Sections with varying thickness can solidify at different rates, causing premature freezing and flow blockages.

- Improper Gate Placement: Gates positioned too far from critical areas may fail to deliver adequate material, resulting in incomplete filling.

- Inadequate Runner Size: Runners that are too narrow or long can restrict flow, especially under high-viscosity conditions.

- High Injection Speed or Pressure Variability: Inconsistent parameters may prevent uniform filling of complex cavities, increasing the risk of flow deficiencies.

Design Strategies to Prevent Flow Deficiencies

- Optimized Runner Layout: Strategic placement of runners and gates ensures uniform material distribution to all critical sections.

- Balanced Multi-Cavity Design: Ensuring each cavity receives an equal share of molten plastic reduces flow imbalance.

- Temperature-Controlled Zones: Maintaining consistent mold temperature prevents premature solidification in narrow or thin sections.

- Polished and Coated Surfaces: Smooth cavity surfaces reduce friction and improve flow, reducing the risk of short shots.

- Adaptive Gate Design: Using variable-size gates or multiple gates for complex regions ensures sufficient material flow.

Material and Process Considerations

- High-Quality Resin: Consistent viscosity and proper drying reduce resistance in the flow path and prevent premature solidification.

- Optimized Injection Parameters: Proper temperature, pressure, and injection speed are crucial to fill intricate sections without causing defects.

- Flow Simulation Analysis: Utilizing software simulations before production helps predict flow issues and adjust runner or gate design.

- Cycle Time Optimization: Allowing adequate injection and cooling time prevents early freezing in challenging mold regions.

Inspection and Quality Assurance Practices

- Visual Inspection: Early detection of underfilled areas or incomplete sections ensures corrective measures can be applied promptly.

- Non-Destructive Testing: Techniques such as ultrasonic inspection or CT scanning can identify internal voids or flow shortages without damaging the product.

- Process Monitoring: Continuous monitoring of injection pressure, temperature, and material flow ensures consistent performance.

- Feedback for Iterative Improvement: Data from inspections can be used to refine mold design or adjust process parameters for better flow.

Benefits of Addressing Flow Deficiencies

- Consistent Product Quality: Proper flow ensures all chair parts meet dimensional accuracy and surface finish requirements.

- Reduced Scrap and Waste: Reducing incomplete filling lowers the number of defective chairs, saving material and cost.

- Increased Production Efficiency: Balanced flow reduces cycle interruptions and downtime caused by rework or mold adjustments.

- Enhanced Durability: Uniformly filled components provide better structural strength and longevity.

Ensuring Efficient Complex Chair Production

Producing complex designs using Plastic Chair Mold introduces challenges related to runner and gate adequacy. Insufficient flow can cause underfilled sections, defects, and compromised product integrity. Through strategic mold design, optimized runner and gate placement, careful material selection, and precise process control, these challenges can be effectively mitigated. Regular inspection and feedback loops further enhance production reliability. By addressing flow deficiencies proactively, manufacturers can ensure high-quality, durable, and visually appealing chairs while maintaining efficiency and reducing waste in high-volume production environments.