The injection mold manufacturing process is a critical part of modern industrial production, especially in industries that rely on high-volume, precision plastic parts. But what exactly happens during this complex procedure? How does mould technology ensure consistency and quality? And how has plastic moulding technology evolved to meet today's demands? Let's break it down step by step with clear, practical insights.

What Is the First Step in the Injection Mold Manufacturing Process?

The journey begins with design and engineering.

-

- Concept to CAD: Engineers start by creating a detailed 3D model using CAD software based on the client's product requirements.

- Feasibility Analysis: The design is reviewed for manufacturability, ensuring that it aligns with the capabilities of the injection mold manufacturing process.

- Material Selection: Choosing the right steel or alloy for the mold is crucial, as it affects durability and performance in plastic moulding technology applications.

This initial phase sets the foundation for all subsequent steps in the injection mold manufacturing process.

How Does Mould Technology Shape the Mold Design Phase?

Advanced mould technology plays a vital role in turning concepts into functional molds.

-

- Simulation Tools: Software simulates how molten plastic will flow, helping identify potential defects before production.

- Cooling System Design: Efficient cooling channels are integrated using mould technology to reduce cycle times and improve part quality.

- Ejection System Planning: Engineers design pins and mechanisms that safely release the finished part without damage.

Without modern mould technology, achieving precision and consistency in the injection mold manufacturing process would be nearly impossible.

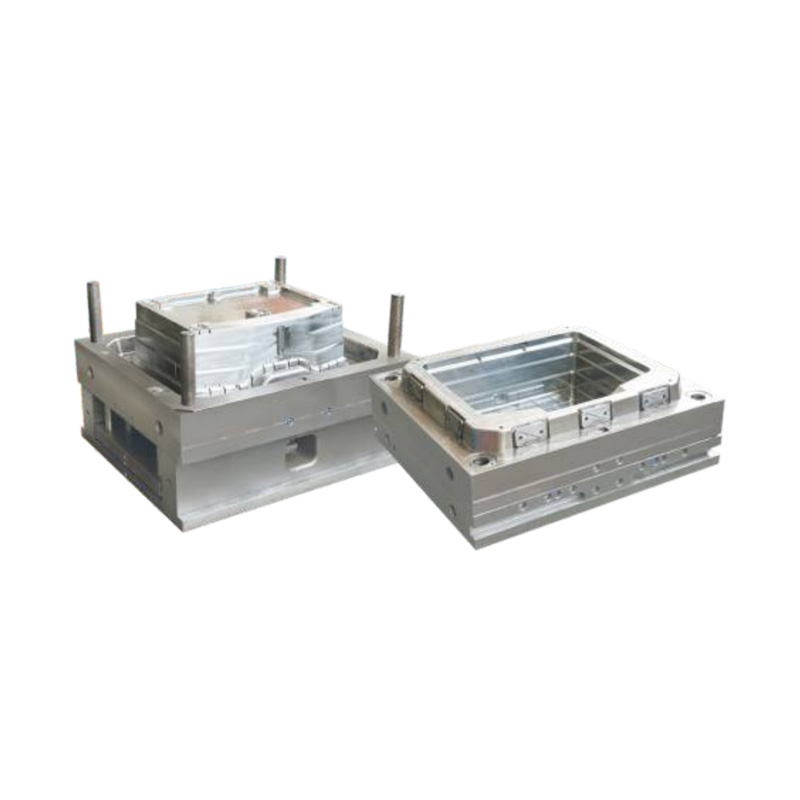

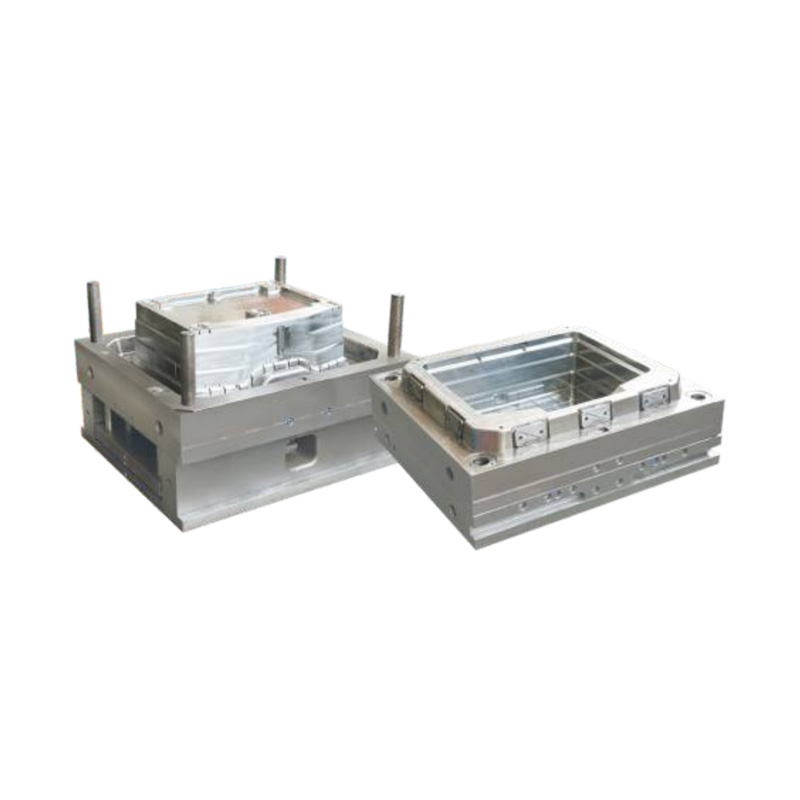

Why Is Mold Making So Critical in Plastic Moulding Technology?

This is where the physical mold is actually built.

-

- CNC Machining: High-precision machines cut the mold cavity and core from metal blocks based on the digital design.

- EDM (Electrical Discharge Machining): Used for intricate details that CNC can't achieve, especially in complex plastic moulding technology applications.

- Polishing and Finishing: Surfaces are smoothed to ensure the final plastic part has a clean, defect-free finish.

Each step must be executed with extreme accuracy, as even minor errors can disrupt the entire injection mold manufacturing process.

When Are Test Runs Conducted in the Injection Mold Manufacturing Process?

After the mold is assembled, it's time for trial production.

-

- First Shot Analysis: The mold is mounted on a plastic moulding technology machine, and initial parts are produced.

- Defect Inspection: Engineers check for short shots, flash, or warping—common issues in early injection mold manufacturing process stages.

- Adjustments: Based on test results, parameters like pressure, temperature, and cooling time are fine-tuned using advanced mould technology.

These test runs ensure the mold performs reliably before full-scale production begins.

How Does Quality Assurance Fit Into the Injection Mold Manufacturing Process?

Quality checks are embedded throughout the entire workflow.

-

- Dimensional Accuracy: Each mold component is measured to ensure it meets exact specifications.

- Durability Testing: Molds undergo stress tests to confirm they can withstand repeated use in plastic moulding technology environments.

- Final Approval: Only after passing all inspections is the mold approved for mass production.

This rigorous approach guarantees that every injection mold manufacturing process delivers consistent, high-quality results.

What Role Does Plastic Moulding Technology Play in Mass Production?

Once the mold is finalized, it's ready for large-scale use.

-

- High-Speed Production: The completed mold is installed in injection machines to produce thousands of identical parts.

- Automation Integration: Modern plastic moulding technology allows seamless integration with robotic arms and conveyor systems.

- Long-Term Reliability: Thanks to robust mould technology, molds can last for hundreds of thousands of cycles with minimal maintenance.

The success of mass production hinges on a well-executed injection mold manufacturing process.

Can the Injection Mold Manufacturing Process Be Customized?

Absolutely—customization is one of its biggest strengths.

-

- Industry-Specific Designs: Whether for medical devices or automotive parts, the injection mold manufacturing process can be tailored to unique needs.

- Multi-Cavity Molds: To increase output, molds can be designed with multiple cavities using advanced mould technology.

- Material Flexibility: The process supports a wide range of plastics, adapting to different plastic moulding technology requirements.

This flexibility makes the injection mold manufacturing process indispensable in today's manufacturing landscape.

Understanding the injection mold manufacturing process is key to producing high-quality plastic components. From initial design to final production, each stage relies on cutting-edge mould technology and evolving plastic moulding technology. By mastering these steps, manufacturers can achieve precision, efficiency, and scalability in every project.