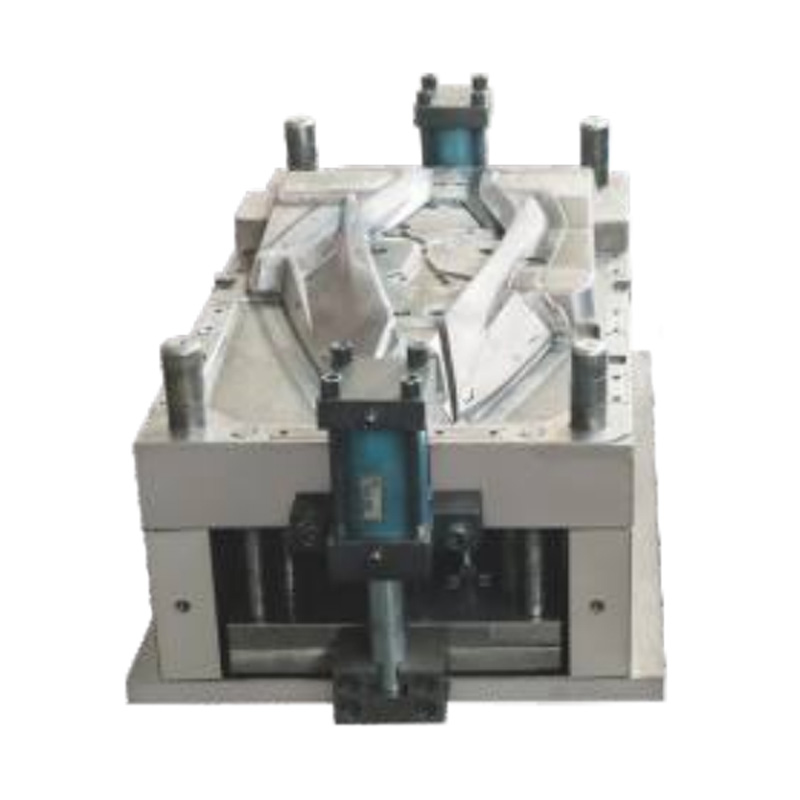

Household Washing Machine Parts Injection Mold

The injection mold for household washing machine parts is an important...

The automotive industry is constantly evolving, driven by the need for lighter, more efficient, and cost-effective vehicles. One of the most transformative technologies enabling this shift is plastic injection molding automotive parts. From dashboards to engine covers, this manufacturing method is revolutionizing how cars are built. But what makes it so essential? How do automotive molds and automotive parts machining fit into the bigger picture?

Lighter vehicles mean better fuel efficiency and lower emissions—two top priorities in today's automotive market.

This shift is only possible with precision automotive molds that ensure consistent part quality.

Today's cars demand complex shapes and integrated features that traditional methods struggle to achieve.

This level of design freedom is unmatched by conventional automotive parts machining.

Yes—and significantly. Cost efficiency is one of the biggest drivers behind the adoption of this technology.

| Cost Factor | Traditional Machining | Plastic Injection Molding |

| Material Waste | High | Low |

| Labor Requirements | High | Low (automated) |

| Production Speed | Slow | Fast (high-volume) |

| Tooling Long-Term Value | Moderate | High (with durable automotive molds) |

Once the initial automotive molds are created, producing thousands of parts becomes highly economical. This scalability makes plastic injection molding automotive parts ideal for mass production.

In the auto industry, part-to-part consistency is not just desirable—it's mandatory.

Reliable automotive molds are the backbone of this consistency, ensuring every part performs as expected.

Sustainability is no longer optional—it's a core requirement for automakers.

This eco-friendly profile aligns perfectly with global emissions regulations and consumer expectations.

Absolutely. In fact, it's the preferred method for large-scale manufacturing.

Compared to automotive parts machining, which is often slower and more labor-intensive, plastic injection molding automotive parts offers unmatched efficiency.

Many people assume plastic is less durable than metal—but that's a myth.

With the right automotive molds and material selection, plastic parts perform as reliably as machined metal components.

Plastic injection molding automotive parts is not just a trend—it's a fundamental shift in how vehicles are designed and built. When combined with advanced automotive molds and smarter manufacturing strategies, it outperforms traditional automotive parts machining in cost, speed, and innovation. As the industry moves toward electric and autonomous vehicles, this technology will play an even greater role in shaping the future of mobility.