The world of industrial moulding is the backbone of modern manufacturing, producing everything from automotive components to consumer electronics. Success in high-volume production hinges on navigating the complexities of tooling, process control, and material science.

Let's delve into the key hurdles faced in industrial mold manufacturing and the practical solutions that keep the industry moving forward.

1. The High Stakes of Tooling: Initial Cost and Lead Time

The Challenge:

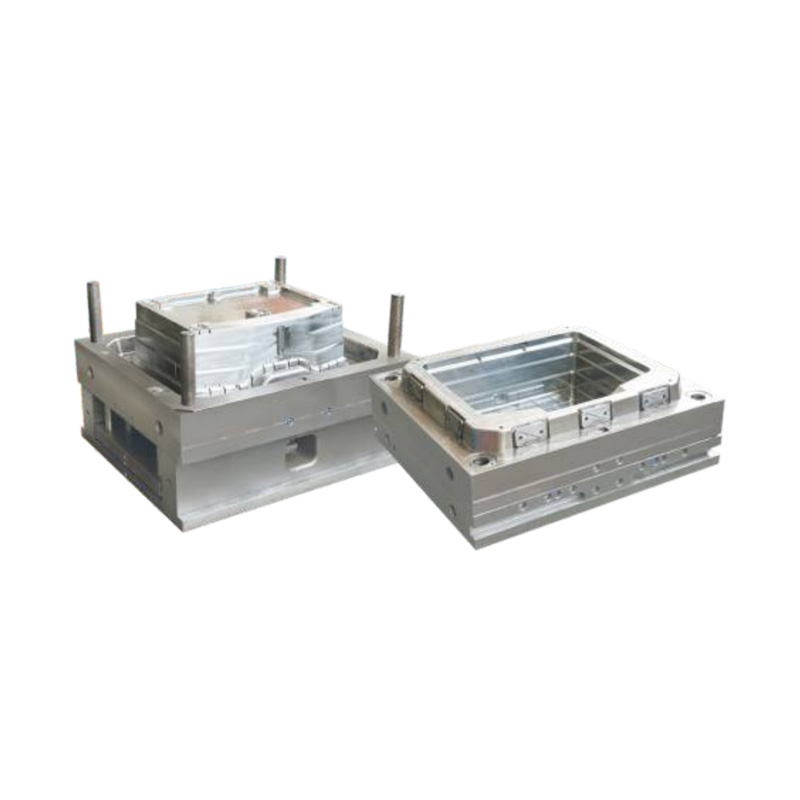

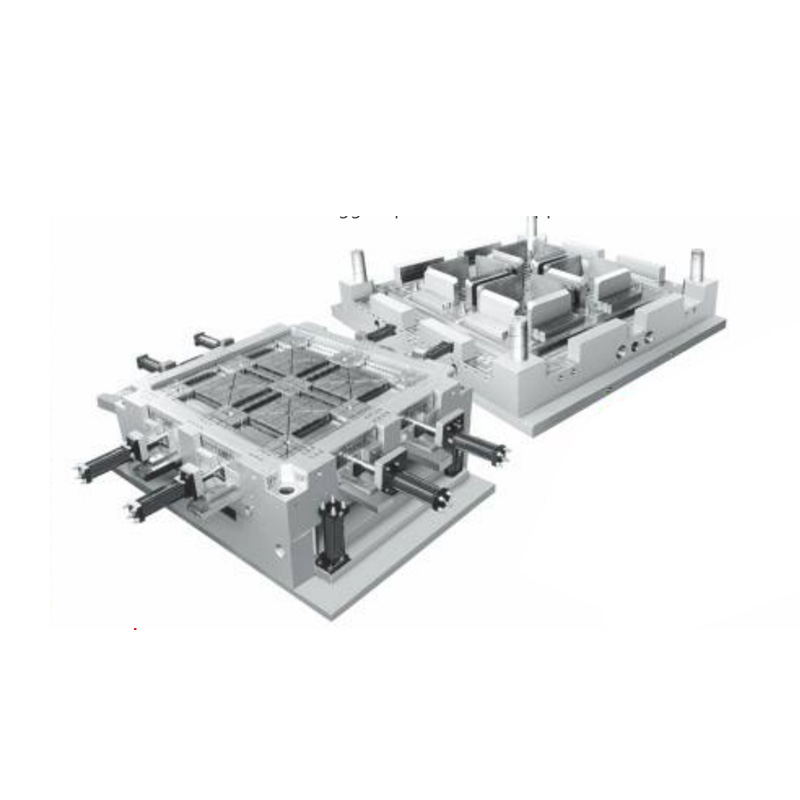

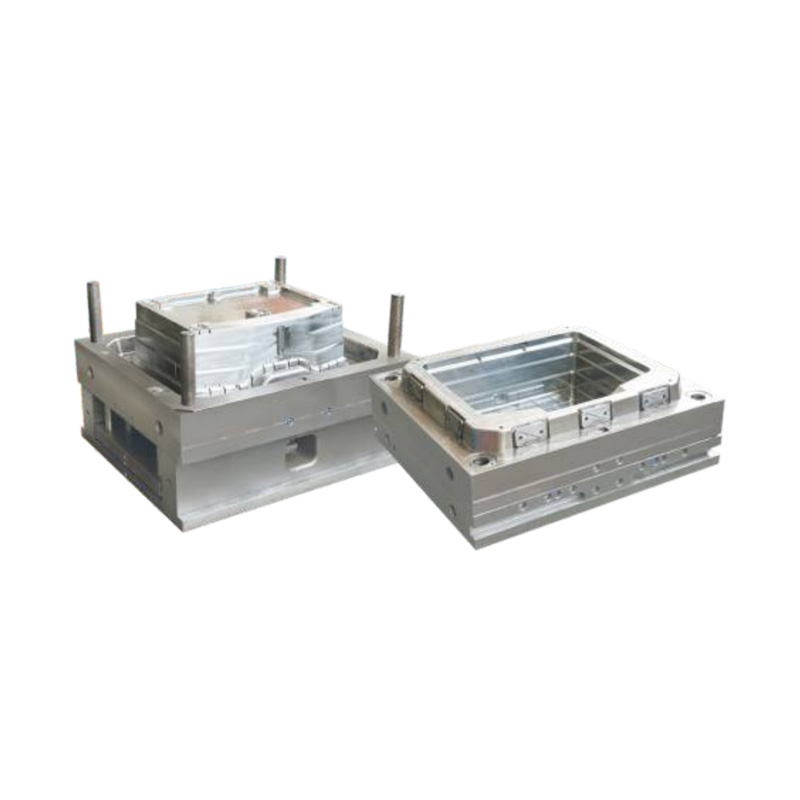

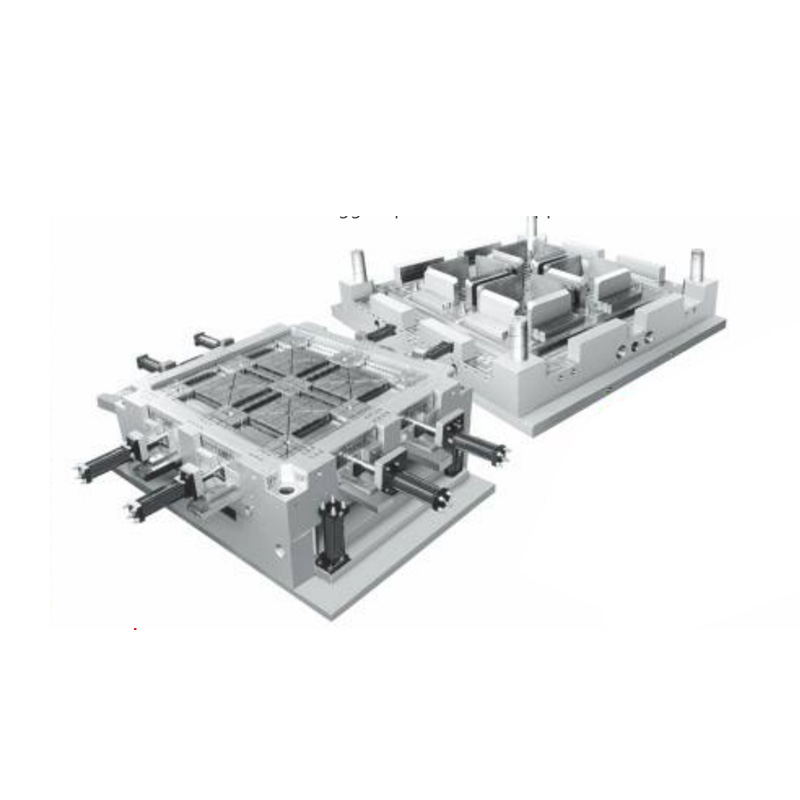

The journey of any mass-produced part begins with the industrial mould. These are not simple tools; they are high-precision, often massive blocks of hardened steel, engineered to withstand millions of cycles. The primary challenge is their exorbitant initial cost and long lead times. A complex, multi-cavity industrial mould can cost hundreds of thousands of dollars and take months to design, machine, and validate. This represents a significant financial risk, especially for new products with unproven market success.

The Solutions:

-

- Advanced Simulation Software: Utilizing Moldflow or similar analysis software allows engineers to simulate the molding process digitally before a single block of steel is cut. This virtual testing identifies potential issues like air traps, weld lines, and sink marks, enabling design optimizations that prevent costly mold rework.

- Collaborative Design (DFM): Implementing a rigorous Design for Manufacturability (DFM) process ensures the product is designed with the industrial moulding process in mind. Early collaboration between product designers and mold makers can simplify geometry, recommend appropriate draft angles, and specify tolerances, making the final industrial mold manufacturing phase smoother and faster.

- Modular Mold Bases: Using standardized, pre-fabricated mold bases can reduce both cost and lead time. Customization is then focused only on the cavity and core inserts, streamlining the manufacturing process.

2. Achieving Consistent Quality: Process Control and Variation

The Challenge:

In a high-volume industrial moulding environment, microscopic variations can lead to massive amounts of scrap. Factors like material viscosity fluctuations, minor temperature shifts, and machine wear can cause defects such as short shots, flash, and dimensional instability. Maintaining a golden cycle consistently across millions of shots is a formidable task.

The Solutions:

-

- Scientific Molding Principles: Moving away from traditional tribal knowledge and guesswork, Scientific Molding relies on data. It involves establishing a precise, repeatable process by characterizing the material and controlling key variables like pressure, temperature, and cooling time with extreme precision. This data-driven approach is fundamental to robust industrial mold manufacturing and process setup.

- Industrial Internet of Things (IIoT) and Real-Time Monitoring: Sensors embedded within the industrial mould and the molding machine can continuously monitor conditions. This data is fed into a central system that can flag deviations in real-time, allowing for proactive adjustments and preventing the production of defective parts. This transforms the industrial moulding process from reactive to predictive.

3. The Perpetual Battle: Wear, Maintenance, and Downtime

The Challenge:

An industrial mould is a capital asset that is constantly under assault. The high-pressure injection of abrasive or corrosive polymers, combined with continuous thermal cycling, leads to wear on critical components like gates, vents, and sliding cores. Unplanned downtime for mold repair and maintenance is incredibly costly, halting production and delaying deliveries.

The Solutions:

-

- Proactive Preventive Maintenance (PM): Implementing a strict, scheduled PM schedule is non-negotiable. This includes disassembly, cleaning, inspection for wear, and replacement of wear-prone components before they fail. A well-documented PM program extends the life of the tooling and ensures consistent part quality.

- Advanced Surface Treatments and Coatings: Technologies like Nickel-Teflon plating, Chromium Nitride (CrN), and Diamond-Like Carbon (DLC) coatings are applied to the industrial mould surfaces. These treatments significantly increase hardness, reduce friction, and enhance release properties, thereby resisting wear and corrosion and extending the mold's service life.

- Spare Parts Inventory: For high-volume production lines, keeping a full set of critical spare components (e.g., cores, ejector pins, sensors) on hand allows for rapid mold repair, minimizing press downtime.

4. Navigating the Material Maze: Consistency and Supply Chain

The Challenge:

The quality of the raw polymer is as critical as the quality of the industrial mould. Variations between different batches of resin—in melt flow index, moisture content, or additive concentration—can disrupt a finely tuned process. Furthermore, global supply chain disruptions can halt production entirely if a specific material becomes unavailable.

The Solutions:

-

- Rigorous Material Certification and Testing: Partnering with reputable material suppliers who provide certified data sheets for every batch is essential. In-house testing of incoming material ensures it meets the required specifications before it enters the production hopper.

- Proper Material Handling and Drying: Many engineering plastics are hygroscopic (water-absorbing). Implementing centralized drying systems with strict protocols prevents moisture-related defects, which is a cornerstone of reliable industrial moulding.

- Dual-Sourcing and Material Auditing: Qualifying multiple material suppliers for the same grade of plastic provides a crucial buffer against supply chain issues. This requires upfront effort but is a key strategy for mitigating risk in large-scale industrial mold manufacturing projects.

Scaling industrial moulding processes is a complex ballet of precision engineering, data-driven management, and strategic foresight. The challenges in tooling, quality, maintenance, materials, and labor are significant, but not insurmountable.